1 4 butynediol Supplier – High Purity, Bulk & Fast Delivery

1 4 Butynediol is a key solution in the Chemical manufacturing industry industry, specifically within Organic chemicals and Chemical intermediates. This article explores how Hebei Tenger Chemical Technology Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- 1 4 Butynediol Overview

- Benefits & Use Cases of 1 4 Butynediol in Chemical intermediates

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Chemical manufacturing industry

- Conclusion on 1 4 Butynediol from Hebei Tenger Chemical Technology Co., Ltd.

1 4 Butynediol Overview

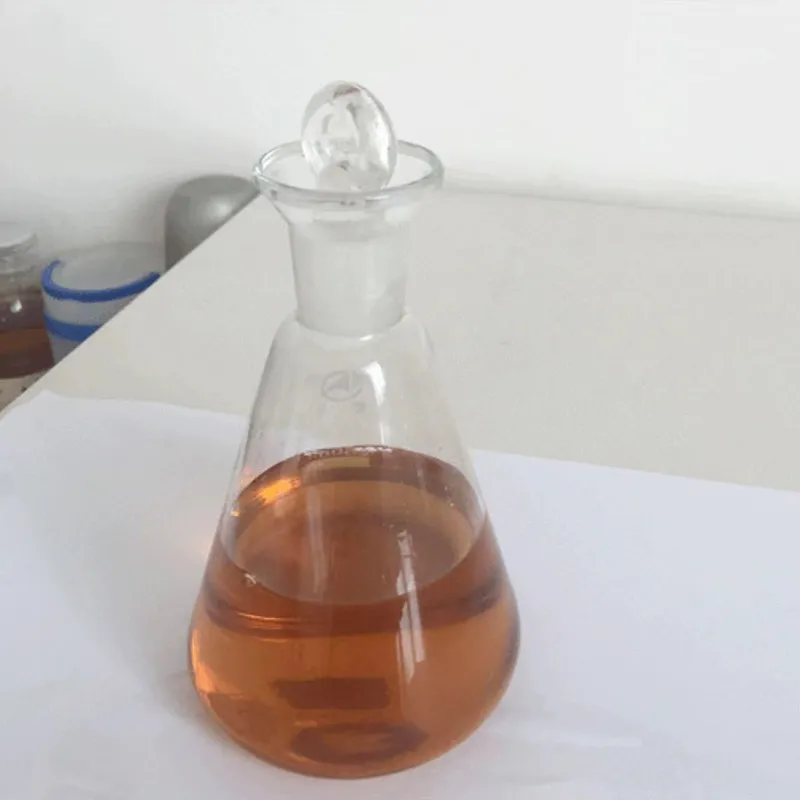

1 4 Butynediol—also known as 2-butyne-1,4-diol (BYD)—is a highly versatile alkyne-diol intermediate widely used across organic synthesis routes in coatings, polymers, plating additives, pharmaceuticals, and agrochemical chains. Chemically, it features a central C≡C bond flanked by two hydroxymethyl groups, enabling selective hydrogenation, esterification, etherification, and addition reactions. To clarify common terminology in the alkyne family: the 2-butyne structural formula is CH3–C≡C–CH3 (2-butyne formula C4H6), while the 1-butyne structure is CH3–CH2–CH2–C≡CH. In contrast, 1 4 Butynediol (C4H6O2) places hydroxyl functionality at both ends, delivering markedly different reactivity and value in downstream chemistry.

In industrial practice, 1 4 Butynediol is a cornerstone of acetylene-formaldehyde chemistry and an established precursor to 1,4-butenediol and 1,4-butanediol via catalytic hydrogenation. Its balanced polarity and alkyne functionality make it a reliable building block for specialty monomers, plasticizers, and fine chemical intermediates. Hebei Tenger Chemical Technology Co., Ltd. supplies high-purity 1 4 Butynediol supported by rigorous quality control and consistent batch-to-batch performance—attributes that B2B buyers in the Chemical manufacturing industry value for stable plant operation and predictable yields.

Benefits & Use Cases of 1 4 Butynediol in Chemical intermediates

For chemical intermediate producers, 1 4 Butynediol unlocks multiple high-value routes. It is a preferred substrate for hydrogenation to 1,4-butenediol and 1,4-butanediol, feeding polyurethane, polyester, and solvent chains. In electroplating chemistry, 1 4 Butynediol is widely adopted as a functional additive/brightener component in acid copper and nickel systems, helping improve leveling, brightness, and deposit uniformity. Its bifunctionality also enables synthesis of diesters and reactive diluents used in radiation-curable coatings, adhesives, and specialty resins. The compound’s high solubility and controlled reactivity streamline formulation work and downstream conversions, often simplifying purification and reducing rework.

Hebei Tenger Chemical Technology Co., Ltd. focuses on reliable supply, consistent assay, and clean impurity profiles—critical factors for catalyst life in hydrogenation and consistent plating outcomes. Customers benefit from application-oriented technical support, tailored packaging options, and documentation that accelerates qualification. When comparing intermediates, 1 4 Butynediol’s combination of diol functionality and an internal alkyne provides a distinct competitive advantage: it is both a robust building block and a fine-tuning tool for selectivity in advanced synthesis.

Cost, Maintenance & User Experience

Total cost of ownership for 1 4 Butynediol hinges on three drivers: supply reliability, conversion efficiency, and quality consistency. A dependable, specification-tight product reduces catalyst fouling in hydrogenation, limits off-spec plating runs, and minimizes downtime—directly impacting yield and labor costs. Hebei Tenger Chemical Technology Co., Ltd. emphasizes stable sourcing and robust QC, helping B2B buyers realize better ROI through fewer process interruptions and more predictable throughput.

From a handling perspective, 1 4 Butynediol is a low-volatility, solid/solution product that stores well in closed containers under cool, dry conditions away from oxidants and strong acids. Routine best practices—clean transfer lines, moisture control, and adherence to SDS guidance—help preserve quality and extend shelf stability. Procurement and technical teams value the user experience when materials arrive ready for line charging, accompanied by clear COA data and responsive support. These service elements, combined with competitive pricing, typically lower the effective cost per ton of converted intermediate or finished additive.

Sustainability & Market Trends in Chemical manufacturing industry

Across the global Chemical manufacturing industry, three forces shape the 1 4 Butynediol landscape: regulatory alignment, process intensification, and decarbonization goals. Producers are prioritizing safer chemistries, better atom economy, and lower energy footprints. For alkyne diols, selective hydrogenation and high-yield esterification routes are increasingly optimized to reduce waste and improve lifecycle metrics. Compliance with frameworks such as REACH or TSCA (as applicable) and continuously updated SDS/COA transparency are now baseline expectations among international buyers.

Hebei Tenger Chemical Technology Co., Ltd. positions 1 4 Butynediol within this forward-looking context. The company supports customers with dependable quality, documentation for regulatory due diligence, and process-minded technical input to help reduce solvent loads, cut reprocessing, and elevate first-pass yield. As demand rises in sectors like performance coatings, electroplating, and polyurethane chains, Tenger’s focus on eco-conscious practices and operational excellence helps partners align with corporate sustainability targets without compromising productivity.

Conclusion on 1 4 Butynediol from Hebei Tenger Chemical Technology Co., Ltd.

As a versatile alkyne-diol, 1 4 Butynediol is integral to high-performance Chemical intermediates—powering routes to polyol chains, plating additives, and specialty monomers. For B2B decision makers, consistent quality and secure supply are decisive. Hebei Tenger Chemical Technology Co., Ltd. delivers both, backed by application-aware support and reliable documentation that accelerate qualification and scale-up. Ready to optimize your supply and formulations? Contact us: email: yanzhe@tengerchemical.com. Visit our website: https://www.tengerchemical.com

-

Comprehensive Guide to 621 Flavour Enhancer: Safety, Uses, and SuppliersNewsNov.18,2025

-

Comprehensive Guide to 551 Anti Caking Agent – Benefits, Uses, and SuppliersNewsNov.17,2025

-

Comprehensive Guide to 500 Food Additives | Global Food Industry InsightsNewsNov.15,2025

-

Comprehensive Guide to 481 Emulsifier – Stability, Uses, and InnovationsNewsNov.15,2025

-

477 Emulsifier: Versatile Solutions for Industrial Stability & SustainabilityNewsNov.15,2025

-

472e Emulsifier: Durable Design Meets Industrial EfficiencyNewsNov.14,2025

-

471 Food Additive: Industrial Solutions from TengerChemicalNewsNov.14,2025

Hebei Tenger Chemical Technology Co., Ltd. focuses on the chemical industry and is committed to the export service of chemical raw materials.

-

view more DiethanolisopropanolamineIn the ever-growing field of chemical solutions, diethanolisopropanolamine (DEIPA) stands out as a versatile and important compound. Due to its unique chemical structure and properties, DEIPA is of interest to various industries including construction, personal care, and agriculture. -

view more TriisopropanolamineTriisopropanolamine (TIPA) alkanol amine substance, is a kind of alcohol amine compound with amino and alcohol hydroxyl, and because of its molecules contains both amino and hydroxyl. -

view more Tetramethyl Thiuram DisulfideTetramethyl thiuram disulfide, also known as TMTD, is a white to light-yellow powder with a distinct sulfur-like odor. It is soluble in organic solvents such as benzene, acetone, and ethyl acetate, making it highly versatile for use in different formulations. TMTD is known for its excellent vulcanization acceleration properties, which makes it a key ingredient in the production of rubber products. Additionally, it acts as an effective fungicide and bactericide, making it valuable in agricultural applications. Its high purity and stability ensure consistent performance, making it a preferred choice for manufacturers across various industries.