Exploring the Properties and Applications of Acrylonitrile Butadiene Rubber NBR in Industry

A Comprehensive Overview of Acrylonitrile Butadiene Rubber (NBR)

Acrylonitrile butadiene rubber, commonly referred to as NBR, is a synthetic rubber that combines properties from both acrylonitrile and butadiene. This unique blend lends itself to a variety of applications and has given NBR a prominent place in numerous industries, particularly in the production of seals, gaskets, hoses, and various other products that require durability and resistance to harsh conditions.

Properties and Composition of NBR

NBR is synthesized through the polymerization of acrylonitrile and butadiene, leading to a copolymer that exhibits remarkable resistance to oil, fuel, and other chemicals. The percentage of acrylonitrile in the compound can be varied—typically ranging from 15% to 50%—which directly influences the rubber's properties. A higher acrylonitrile content tends to improve the material’s oil and fuel resistance but may reduce its flexibility and low-temperature performance.

One of the most notable features of NBR is its excellent resistance to abrasion, making it an ideal choice for products that undergo significant wear and tear. Additionally, NBR maintains a good balance of tensile strength, resilience, and aging stability. This combination of properties makes NBR highly sought after in applications where exposure to harsh environments is common.

Applications of NBR

The versatility of NBR is evident in the diverse range of applications it serves. Its exceptional chemical resistance is particularly advantageous for industries involving transportation fuels and hydraulic fluids. Therefore, it is widely used in manufacturing O-rings, seals, and gaskets. In the automotive sector, NBR components can be found in fuel hoses, oil seals, and vibration dampers due to their ability to withstand the aggressive conditions found in engines.

Furthermore, NBR is extensively employed in the production of conveyor belts, tires, and industrial rubber products, where resistance to oil and wear is crucial. Additionally, it is utilized in the creation of adhesive formulations and coatings—where its bonding capabilities and elasticity contribute to enhanced performance.

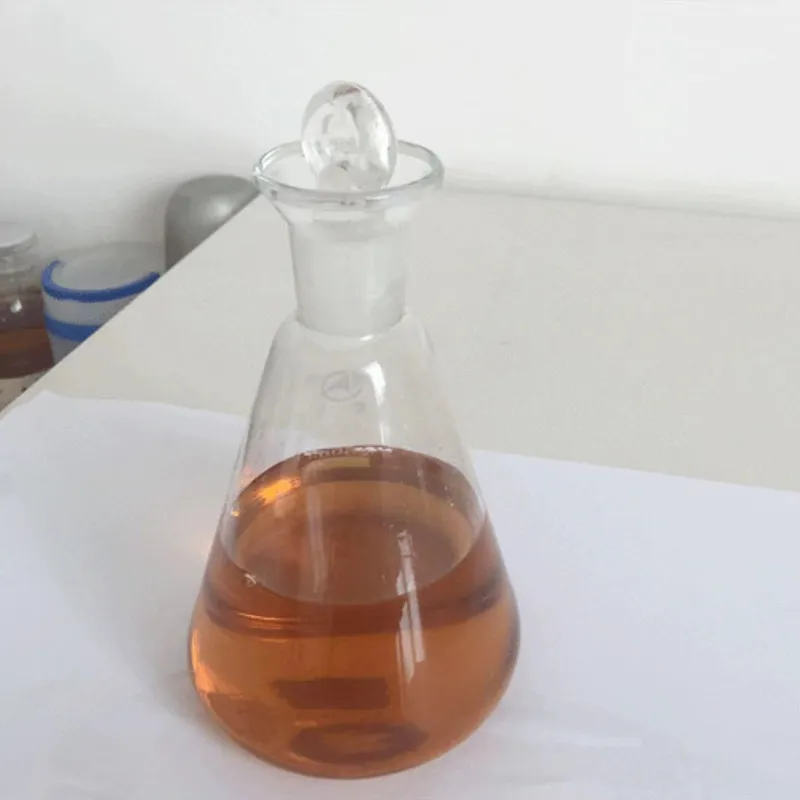

acrylonitrile butadiene rubber nbr

In the medical field, NBR finds use in various applications such as medical tubing and gloves, particularly where chemical resistance is paramount. While it is generally not as flexible as some other types of rubber, advancements in NBR formulations have led to improved elasticity and a wider range of potential uses.

Processing Techniques for NBR

The processing of NBR requires specific techniques tailored to exploit its unique properties effectively. Common methods for shaping NBR include extrusion, molding, and calendaring. These processing techniques allow manufacturers to produce NBR products in varying shapes and sizes, meeting the specific requirements of different applications.

Additives also play a critical role in enhancing the performance of NBR. By incorporating various fillers, plasticizers, antioxidants, and curing agents, manufacturers can improve the rubber’s durability, flexibility, and heat resistance. This versatility in formulation enables NBR to compete effectively with other synthetic rubbers and elastomers in the marketplace.

Environmental Considerations and Future Outlook

As with many synthetic materials, the production and disposal of NBR raise environmental concerns. The need for more sustainable practices in the rubber industry has prompted research into bio-based alternatives and recycling methods. Efforts are being made to develop more eco-friendly rubber formulations and processing methodologies that minimize environmental impact.

Looking ahead, the demand for NBR is expected to grow as industries continue to seek high-performance materials for increasingly sophisticated applications. Technological advancements in polymer science may also lead to the development of enhanced NBR variants with improved properties, further expanding its market reach.

In conclusion, acrylonitrile butadiene rubber (NBR) is a vital material in modern manufacturing, offering a blend of exceptional resistance and versatility. Its ability to withstand extreme conditions makes it indispensable in various applications, from automotive to medical. As industries evolve and environmental considerations gain prominence, NBR is poised to adapt, ensuring its relevance in the future landscape of synthetic materials.

-

Buy High-Quality Trichloroisocyanuric Acid for Sale | TCCA 90% SupplierNewsAug.30,2025

-

Pure Sodium Dichloroisocyanurate Dihydrate | Powerful DisinfectantNewsAug.29,2025

-

Industrial Chemicals: Quality & Purity for Every IndustryNewsAug.28,2025

-

Nitrile Rubber Honoring Strict Production StandardsNewsAug.22,2025

-

Aspartame Ingredients Honoring Food Safety ValuesNewsAug.22,2025

-

Fertilizer for Balanced Plant NutritionNewsAug.22,2025

-

Cyanide Gold Processing with High Purity AdditivesNewsAug.22,2025

Hebei Tenger Chemical Technology Co., Ltd. focuses on the chemical industry and is committed to the export service of chemical raw materials.

-

view more DiethanolisopropanolamineIn the ever-growing field of chemical solutions, diethanolisopropanolamine (DEIPA) stands out as a versatile and important compound. Due to its unique chemical structure and properties, DEIPA is of interest to various industries including construction, personal care, and agriculture. -

view more TriisopropanolamineTriisopropanolamine (TIPA) alkanol amine substance, is a kind of alcohol amine compound with amino and alcohol hydroxyl, and because of its molecules contains both amino and hydroxyl. -

view more Tetramethyl Thiuram DisulfideTetramethyl thiuram disulfide, also known as TMTD, is a white to light-yellow powder with a distinct sulfur-like odor. It is soluble in organic solvents such as benzene, acetone, and ethyl acetate, making it highly versatile for use in different formulations. TMTD is known for its excellent vulcanization acceleration properties, which makes it a key ingredient in the production of rubber products. Additionally, it acts as an effective fungicide and bactericide, making it valuable in agricultural applications. Its high purity and stability ensure consistent performance, making it a preferred choice for manufacturers across various industries.