High-Purity 1 4 butynediol for Advanced Synthesis & Coatings

1 4 Butynediol is a key solution in the Chemical manufacturing industry industry, specifically within Organic chemicals and Chemical intermediates. This article explores how Hebei Tenger Chemical Technology Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- 1 4 Butynediol Overview

- Benefits & Use Cases of 1 4 Butynediol in Chemical intermediates

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Chemical manufacturing industry

- Conclusion on 1 4 Butynediol from Hebei Tenger Chemical Technology Co., Ltd.

1 4 Butynediol Overview

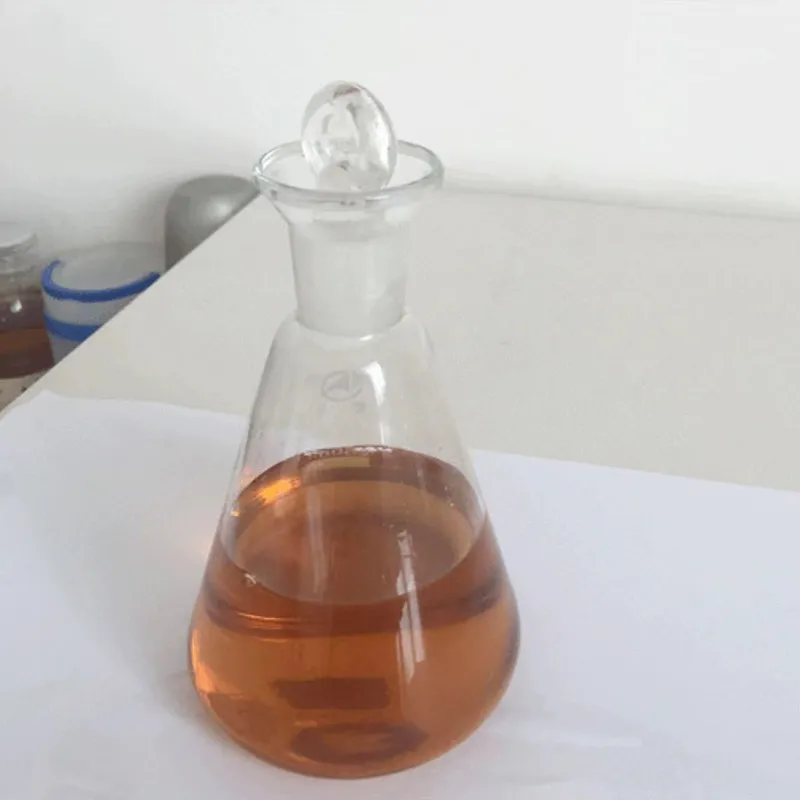

1 4 Butynediol (also known as 2-butyne-1,4-diol; CAS 110-65-6) is an acetylenic diol widely used as a versatile intermediate across the Organic chemicals value chain. With the molecular formula C4H6O2, its structure HO–CH2–C≡C–CH2–OH features a central internal alkyne, enabling selective hydrogenation, addition, and functionalization reactions. This reactivity makes it a pivotal starting point to downstream products such as 1,4-butanediol (BDO), 1,4-butenediol, and tetrahydrofuran (THF). For B2B decision makers, consistent assay and impurity control of 1 4 Butynediol directly translate into higher yields, cleaner reaction profiles, and predictable plant performance.

From a chemistry perspective, understanding alkyne isomerism helps explain behavior in synthesis: the 2-butyne formula is C4H6 and the 2-butyne structural formula is CH3–C≡C–CH3, distinct from the terminal alkyne represented by the 1-butyne structure CH≡C–CH2–CH3. 1 4 Butynediol embeds the internal alkyne motif (akin to 2-butyne) while adding primary hydroxyls, combining selective alkyne reactivity with diol functionality. Hebei Tenger Chemical Technology Co., Ltd. supplies high-purity 1 4 Butynediol with rigorous QC, offering typical specifications such as high assay content, low moisture, and controlled aldehyde/acid impurities to support critical polymer and fine-chemical syntheses. Backed by an ISO-aligned quality management approach and reliable logistics, Tenger ensures consistent, auditable lots suitable for regulated markets.

Benefits & Use Cases of 1 4 Butynediol in Chemical intermediates

In Chemical intermediates, 1 4 Butynediol is valued for its dual functionality: a reactive C≡C bond and two primary alcohols. Typical pathways include selective hydrogenation to 1,4-butenediol and subsequent hydrogenation to BDO, which can further convert to THF and poly(tetramethylene ether) glycol (PTMEG) used in spandex and elastomers. It also serves as a building block for specialty monomers, crosslinkers in polyurethane systems, and intermediates for agrochemicals and pharmaceuticals where precise control of unsaturation is essential. Its predictable reactivity enables streamlined synthesis routes with fewer steps and cleaner workups.

- Selective hydrogenation and addition chemistry driven by the internal alkyne

- High reactivity of primary hydroxyls for esterification, etherification, and urethane formation

- Consistent purity for reduced side reactions and simplified downstream purification

Hebei Tenger Chemical Technology Co., Ltd. leverages process know-how to deliver stable, on-spec supply—available in solid form or tailored solutions—helping formulators and process chemists de-risk scale-up. Customers choose Tenger for competitive lead times, documentation support (TDS, SDS, COA), and technical guidance that aligns 1 4 Butynediol grades to specific catalytic systems and reactor conditions.

Cost, Maintenance & User Experience

Total cost of ownership with 1 4 Butynediol hinges on more than unit price. High, consistent assay reduces catalyst fouling and off-spec batches, minimizing unplanned downtime and waste disposal costs. Reliable supply and packaging options—such as lined drums, big bags, or solution formats—lower handling complexity and improve throughput. For continuous hydrogenation trains converting 1 4 Butynediol to BDO/THF, stable feed quality translates into tighter process control and better asset utilization, boosting ROI across multi-year campaigns.

In-use feedback from Organic chemicals producers highlights clean reaction profiles and reproducible conversion under standard catalytic conditions. Storage best practices include keeping containers tightly closed, in a cool, dry, and well-ventilated area away from strong oxidizers; for solids, gentle heating in a controlled environment can aid handling if solidification occurs. Hebei Tenger Chemical Technology Co., Ltd. provides guidance on storage, transfer, and melt handling to protect product integrity over shelf life, enabling smoother operations from pilot to plant scale.

Sustainability & Market Trends in Chemical manufacturing industry

Demand for intermediates like 1 4 Butynediol is tied to growth in elastomers, engineering plastics, and specialty chemicals. At the same time, regulatory pressure and customer expectations are accelerating safer chemistries, traceability, and reduced environmental footprints. This affects feedstock choices, process intensification, and waste minimization throughout the value chain—from acetylene/formaldehyde-based synthesis through to hydrogenation and downstream conversions. Buyers increasingly evaluate suppliers on EHS performance, emissions management, and transparent documentation to support audits and compliance in global markets.

Hebei Tenger Chemical Technology Co., Ltd. is committed to forward-thinking practices, emphasizing consistent quality, responsible manufacturing, and continuous improvement in energy and resource efficiency. By offering documentation support and engaging collaboratively on greener process options—such as optimized catalyst utilization, solvent management, and closed-loop utilities—Tenger helps customers meet internal sustainability targets without compromising performance. For decision makers, partnering with a supplier that unites product excellence with operational responsibility is a strategic lever for long-term competitiveness.

Conclusion on 1 4 Butynediol from Hebei Tenger Chemical Technology Co., Ltd.

As a high-value intermediate, 1 4 Butynediol enables efficient routes to BDO, THF, and specialty molecules, delivering dependable performance for Organic chemicals and Chemical intermediates producers. Hebei Tenger Chemical Technology Co., Ltd. combines consistent quality, technical support, and responsive service to reduce risk and enhance ROI from lab to commercial scale. Ready to optimize your supply of 1 4 Butynediol? Contact us: email: yanzhe@tengerchemical.com — Visit our website: https://www.tengerchemical.com

-

What Is a Food Additive? Global Insights, Applications & Future TrendsNewsNov.24,2025

-

968 Sweetener: The Modern Solution for Health-Conscious SweeteningNewsNov.23,2025

-

Discover the Benefits and Uses of 965 Sweetener (Erythritol) | Tenger ChemicalNewsNov.23,2025

-

961 Sweetener - A Next-Gen Sugar Alternative for Health and IndustryNewsNov.23,2025

-

Understanding 960 Sweetener: The Modern Sugar Alternative for Health and IndustryNewsNov.22,2025

-

Everything You Need to Know About 955 950 Sweeteners – Benefits, Uses, and TrendsNewsNov.22,2025

-

953 Sweetener: Global Insights, Applications, and Future TrendsNewsNov.21,2025

Hebei Tenger Chemical Technology Co., Ltd. focuses on the chemical industry and is committed to the export service of chemical raw materials.

-

view more DiethanolisopropanolamineIn the ever-growing field of chemical solutions, diethanolisopropanolamine (DEIPA) stands out as a versatile and important compound. Due to its unique chemical structure and properties, DEIPA is of interest to various industries including construction, personal care, and agriculture. -

view more TriisopropanolamineTriisopropanolamine (TIPA) alkanol amine substance, is a kind of alcohol amine compound with amino and alcohol hydroxyl, and because of its molecules contains both amino and hydroxyl. -

view more Tetramethyl Thiuram DisulfideTetramethyl thiuram disulfide, also known as TMTD, is a white to light-yellow powder with a distinct sulfur-like odor. It is soluble in organic solvents such as benzene, acetone, and ethyl acetate, making it highly versatile for use in different formulations. TMTD is known for its excellent vulcanization acceleration properties, which makes it a key ingredient in the production of rubber products. Additionally, it acts as an effective fungicide and bactericide, making it valuable in agricultural applications. Its high purity and stability ensure consistent performance, making it a preferred choice for manufacturers across various industries.