High-Purity 1 4 Butynediol: Versatile Chemical Intermediate

In the vast landscape of industrial chemistry, certain compounds stand out for their versatile applications and pivotal role in various manufacturing processes. Among these, 1 4 butynediol, also known as BDO or Butynediol, is a cornerstone chemical intermediate. This comprehensive guide delves into the intricate world of 1 4 butynediol, exploring its chemical properties, manufacturing intricacies, diverse applications, and market significance. We aim to provide an in-depth understanding, leveraging industry insights, technical data, and a focus on Google's standards to ensure accuracy, authority, and trustworthiness.

Understanding 1,4-Butynediol: A Chemical Overview and Structural Insights

1 4 butynediol (HOCH₂C≡CCH₂OH) is an organic compound with a unique structure featuring two hydroxyl groups (-OH) at the terminal ends of a four-carbon chain, which also contains an internal triple bond (C≡C). This combination of functional groups gives 1 4 butynediol its distinct reactivity and makes it a highly sought-after building block in organic synthesis.

To clarify its unique positioning, let's briefly compare its structure with related but distinct compounds:

- 1-Butyne Structure: The 1-butyne structure (CH₃CH₂C≡CH) is characterized by a terminal alkyne group, meaning the triple bond is at the end of the carbon chain. It possesses one triple bond and no hydroxyl groups, making its chemical reactivity significantly different from 1 4 butynediol.

- 2-Butyne Formula: The 2-butyne formula (CH₃C≡CCH₃) represents an internal alkyne, where the triple bond is located between the second and third carbon atoms. Like 1-butyne, it lacks hydroxyl groups, limiting its direct use in polymerization reactions where diols are essential.

- 2-Butyne Structural Formula: The 2-butyne structural formula visually represents CH₃-C≡C-CH₃. Its linear structure around the triple bond and the presence of only methyl groups differentiate it from the dihydroxyl structure of 1 4 butynediol, which has reactive -OH groups on both ends.

Industry Trends and Market Dynamics for Butynediol

The global market for 1 4 butynediol is experiencing steady growth, driven by increasing demand from downstream industries such as polyurethanes, spandex fibers, pharmaceuticals, and agricultural chemicals. According to a recent market analysis by Grand View Research, the global 1,4-butanediol market size, which is heavily reliant on 1 4 butynediol as an intermediate, was valued at over USD 6.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth is fueled by expanding end-use applications, particularly in the automotive, construction, and textile sectors.

Furthermore, the shift towards bio-based production methods for 1,4-butanediol, which can also originate from biological routes, influences the demand and pricing dynamics of traditional petrochemical-derived 1 4 butynediol. However, the existing infrastructure and cost-effectiveness of conventional synthesis ensure its continued dominance for many applications. Key market players are investing in research and development to optimize production processes, enhance purity, and explore new application avenues, especially in high-performance materials and sustainable chemical production. The push for more efficient chemical processes and greener synthesis routes continues to shape the market landscape for intermediates like 1 4 butynediol.

Technical Specifications and Properties of 1,4-Butynediol

The efficacy and versatility of 1 4 butynediol stem from its precise physical and chemical properties. Understanding these parameters is crucial for its safe handling, storage, and effective application in various industrial processes. High-quality 1 4 butynediol ensures consistent performance and minimizes impurities that could affect downstream reactions.

Key Parameters of 1,4-Butynediol (Tenger Chemical Standard)

Below is a table summarizing the typical technical parameters for high-grade 1 4 butynediol supplied by Tenger Chemical, crucial for ensuring product quality and performance in demanding applications. These specifications often adhere to international standards, providing a benchmark for quality control and reliability.

| Property | Typical Value | Unit | Standard/Method |

|---|---|---|---|

| Chemical Formula | C₄H₆O₂ | ||

| Molecular Weight | 86.09 | g/mol | |

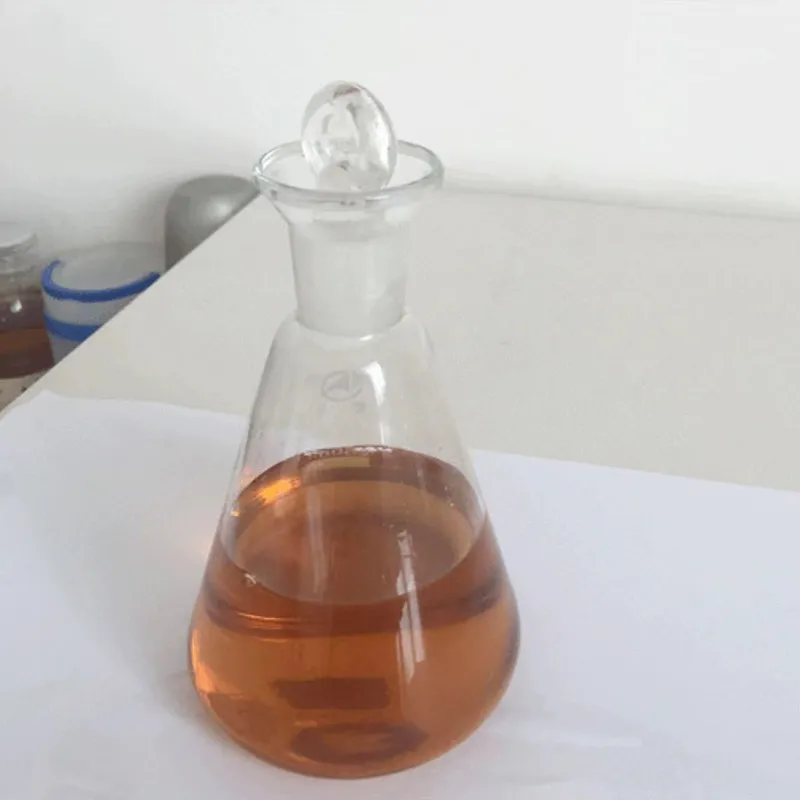

| Appearance | Colorless to Light Yellow Liquid/Solid | Visual Inspection | |

| Purity (min) | 99.0 | % | GC (Gas Chromatography) |

| Melting Point | 58-60 | °C | ASTM D1459 |

| Boiling Point (at 101.3 kPa) | 238-240 | °C | ASTM D1120 |

| Density (25°C) | 1.082 - 1.090 | g/cm³ | ASTM D4052 |

| Refractive Index (nD20) | 1.4720 - 1.4735 | ASTM D1218 | |

| Water Content (max) | 0.1 | % | Karl Fischer Titration |

| Hydroxyl Value | 1290 - 1310 | mg KOH/g | ASTM D4274 |

| Flash Point (Closed Cup) | 124 | °C | ASTM D93 |

| Solubility | Soluble in water, alcohols, ketones |

The Manufacturing Process of 1,4-Butynediol: From Raw Materials to Purity

The production of 1 4 butynediol is a sophisticated chemical engineering feat, predominantly achieved through the Reppe Process, named after German chemist Walter Reppe. This process is a testament to industrial innovation, converting simple feedstocks into a valuable chemical intermediate. The stringent control of process parameters ensures high purity and yield, which are critical for its diverse applications.

Detailed Process Flow: The Reppe Synthesis

The Reppe synthesis for 1 4 butynediol involves the catalytic reaction of acetylene with two molecules of formaldehyde. The overall reaction can be summarized as:

2 HCHO (Formaldehyde) + C₂H₂ (Acetylene) → HOCH₂C≡CCH₂OH (1,4-Butynediol)

Below is a simplified breakdown of the manufacturing process, highlighting key stages and considerations. This process demands precise control and robust equipment to ensure safety, efficiency, and product quality.

-

Raw Material Preparation and Feedstock Management:

- Formaldehyde: Typically supplied as an aqueous solution (e.g., 37-50% concentration). It's crucial to ensure high purity and consistent concentration, often requiring pre-treatment to remove trace impurities.

- Acetylene: Usually generated on-site from calcium carbide or sourced from natural gas/petroleum cracking. Safety protocols for handling acetylene, a highly flammable and explosive gas, are paramount, including pressure and flow rate control.

- Catalyst System: A crucial component is the catalyst, often a copper acetylide based system (e.g., Cu₂O or copper(I) acetylide) supported on an inert material like silica gel or activated carbon. The catalyst facilitates the highly selective addition reaction, minimizing side reactions and maximizing yield.

-

Reaction Section (Ethynylation) – The Core Conversion:

The prepared formaldehyde solution and acetylene gas are fed into a specially designed reactor. This is often a fixed-bed reactor containing the solid copper-based catalyst. The reaction is highly exothermic (releases heat) and typically carried out under specific temperature (e.g., 80-120°C) and pressure (e.g., 0.5-2.0 MPa) conditions to optimize yield and selectivity while managing safety. Efficient heat removal systems (e.g., cooling jackets or internal coils) are integrated to maintain isothermal conditions. The precise control of temperature and pressure is critical to prevent runaway reactions, catalyst deactivation, and the formation of undesirable by-products.

The prepared formaldehyde solution and acetylene gas are fed into a specially designed reactor. This is often a fixed-bed reactor containing the solid copper-based catalyst. The reaction is highly exothermic (releases heat) and typically carried out under specific temperature (e.g., 80-120°C) and pressure (e.g., 0.5-2.0 MPa) conditions to optimize yield and selectivity while managing safety. Efficient heat removal systems (e.g., cooling jackets or internal coils) are integrated to maintain isothermal conditions. The precise control of temperature and pressure is critical to prevent runaway reactions, catalyst deactivation, and the formation of undesirable by-products.

(Visual Concept for Process Flow Diagram: A large cylindrical reactor vessel, labeled "Ethynylation Reactor," with arrows indicating inflow of "Formaldehyde Solution" and "Acetylene Gas" at the top/side. Inside, a section labeled "Catalyst Bed" is shown. An arrow points from the bottom/side of the reactor labeled "Crude 1,4-Butynediol Product" towards the next stage.) -

Separation and Purification – Achieving High Purity:

- Quenching & Cooling: The crude reaction mixture, containing 1 4 butynediol, unreacted formaldehyde, various by-products (like propargyl alcohol, butenetriol), and water, is first rapidly cooled ("quenched") to stop the reaction and prevent further degradation.

- Catalyst Removal: The solid catalyst is efficiently separated from the liquid product stream, often through advanced filtration (e.g., candle filters, plate-and-frame filters) or centrifugation. The separated catalyst is then regenerated for reuse or safely disposed of.

- Multi-Stage Distillation: The liquid stream undergoes multiple stages of distillation, which is the most critical purification step. This complex process separates 1 4 butynediol from water, unreacted formaldehyde, and various by-products based on their boiling points. Vacuum distillation is commonly employed to reduce the boiling temperature, prevent thermal degradation of the product, and improve energy efficiency. The precise control of column temperatures, pressures, and reflux ratios at each stage ensures maximum purity and yield of the final product.

- Crystallization (Optional for High Purity): For very high purity grades, particularly if the product is solid at room temperature, a final crystallization step might be included to further purify the 1 4 butynediol by forming pure crystals from a suitable solvent, followed by drying.

-

Quality Control and Packaging:

The final purified 1 4 butynediol is subjected to rigorous quality control checks against established product specifications using advanced analytical techniques such as Gas Chromatography (GC) for purity, Karl Fischer titration for water content, and other standard tests mentioned in the technical parameters table. Tenger Chemical adheres to strict internal quality benchmarks and international standards. Once validated for purity, appearance, and other critical parameters, the product is safely packaged into appropriate container111s (e.g., steel drums, IBCs, isotanks) under an inert atmosphere (e.g., nitrogen blanket) to prevent oxidation, contamination, and ensure stability during transport and storage.

(Visual Concept for Process Flow Diagram: Arrows flow from "Crude 1,4-Butynediol Product" to "Filtration Unit" (for catalyst removal), then to "Distillation Columns" (multiple stages shown), finally to "Quality Control Lab" and then "Packaging & Storage.")

Manufacturing Process Considerations:

- Product Material & Equipment (Product Material): Components in contact with the reactants and products, especially the catalyst and reactor materials, must be chosen for their superior resistance to corrosion, high temperatures, and pressures. Specialized stainless steel alloys (e.g., 304L, 316L, duplex steels) are commonly used due to their durability and chemical resistance in corrosive environments.

- Manufacturing Process Technology (Manufacturing Process): The primary manufacturing process is chemical synthesis, specifically catalytic ethynylation. The equipment used includes highly specialized reactors, multi-stage distillation columns, high-efficiency heat exchangers, and robust pumps. These components are often fabricated through precise engineering processes such as orbital welding for piping, advanced forging for pressure vessels, and high-precision CNC machining for critical valve components and pump parts to ensure tight tolerances, leak-proof operation, and long service life.

- Inspection Standards (Detection Standards): Tenger Chemical's production facilities adhere to stringent international standards such as ISO 9001:2015 for quality management systems and ISO 14001:2015 for environmental management. All product batches undergo comprehensive testing according to ASTM (American Society for Testing and Materials) methods, and compliance with specific regional regulations like REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) for European markets is meticulously maintained. Internal ANSI/ASME standards for pressure vessel design and fabrication are also followed.

- Usage Lifespan & Durability: While 1 4 butynediol itself is a consumable chemical, the sophisticated equipment used in its manufacture is designed for long service life, typically 15-20 years or more, with regular preventative maintenance. This longevity is achieved through robust material selection and precision manufacturing, highlighting the significant capital investment and advanced engineering involved.

- Typical Application Advantages: In various applications, especially in electroplating or as a chemical intermediate, the high purity and consistent quality of our 1 4 butynediol contribute significantly. For example, in electroplating, it acts as a superior brightening agent and corrosion inhibitor, leading to energy savings by reducing processing time and enhancing anti-corrosion performance and aesthetic finish. In polymerization, its consistent reactivity reduces energy consumption by optimizing reaction kinetics and ensuring higher yields, minimizing waste.

Applications of 1,4-Butynediol: A Versatile Chemical Intermediate Across Industries

The unique chemical structure of 1 4 butynediol, combining both alkyne and diol functionalities, makes it an invaluable intermediate in the synthesis of a wide range of specialty chemicals and polymers. Its reactivity allows for transformations into critical building blocks for numerous industries, demonstrating its broad economic impact.

Diverse Application Scenarios and Industry Impact

The applications of 1 4 butynediol span across multiple sectors, showcasing its versatility and economic importance:

-

Polymer and Plastics Industry (Largest Segment): This is perhaps the most significant application area. 1 4 butynediol is catalytically hydrogenated to produce 1,4-butanediol (BDO), which is a crucial monomer for the production of:

- Tetrahydrofuran (THF): A widely used solvent for PVC, as well as a key precursor to polytetramethylene ether glycol (PTMEG), which is essential for manufacturing highly elastic fibers like Spandex (elastane) and high-performance polyurethane elastomers.

- Polybutylene Terephthalate (PBT): An engineering plastic known for its excellent strength, stiffness, heat resistance, and dimensional stability. PBT is extensively used in the automotive industry (e.g., electrical connectors, sensor housings), electrical and electronic components (e.g., switches, relays), and consumer goods.

- Gamma-Butyrolactone (GBL): A versatile solvent and intermediate for N-methyl-2-pyrrolidone (NMP), used in electronics manufacturing (e.g., photoresist strippers, cleaning agents), coatings, agrochemicals, and as a raw material for pharmaceuticals.

- Polyurethanes (PU): 1 4 butynediol derivatives contribute to the synthesis of various polyurethane types, used in foams (furniture, insulation), coatings (protective and decorative), adhesives, and elastomers (seals, wheels).

- Pharmaceutical Industry: 1 4 butynediol serves as a key precursor in the synthesis of various pharmaceutical compounds. Its high purity is paramount in this sector to ensure product safety, efficacy, and compliance with stringent regulatory standards. Examples include its use in certain anti-HIV drugs, antibiotics, and vitamins.

- Agricultural Chemicals: It is used in the synthesis of specialized pesticides, herbicides, and plant growth regulators. By contributing to effective crop protection and enhancing agricultural productivity, 1 4 butynediol plays a role in global food security.

- Electroplating Industry: 1 4 butynediol acts as a crucial brightening agent and leveling agent in nickel electroplating baths, producing shiny, smooth, and durable metal coatings. In this scenario, its stability and ability to form complexes with metal ions demonstrate its excellent anti-corrosion properties and contribute to efficient plating processes, ultimately saving energy by reducing plating time and improving coating quality and lifespan of plated components. This makes it vital for applications requiring high aesthetic and functional performance.

- Textile Industry: Beyond its role in Spandex production, 1 4 butynediol derivatives are also used in various dyeing and finishing processes to improve the properties of textiles, such as feel, durability, and color fastness.

- Oil and Gas (Petrochemical): While not a primary end-use in this sector, derivatives of 1 4 butynediol can be found in specialized drilling fluids, corrosion inhibitors for pipelines, or as intermediates for certain petrochemical derivatives, owing to its chemical versatility.

- Metallurgy and Surface Treatment: As highlighted in electroplating, its use in surface treatment of metals makes it highly relevant for metallurgical applications focused on enhancing corrosion resistance, wear resistance, and surface aesthetics of metal parts.

Technical Advantages and Quality Assurance of Tenger Chemical's 1,4-Butynediol

The selection of a high-quality supplier for 1 4 butynediol is paramount for consistent production and superior end-product performance in any industrial process. Tenger Chemical, a reputable and established name in the chemical industry, offers 1 4 butynediol with distinct technical advantages, backed by decades of experience and adherence to global standards.

Why Choose Tenger Chemical's 1,4-Butynediol?

Our 1 4 butynediol product stands out due to several key factors that directly benefit our clients' operations and end products:

- Exceptional Purity & Consistency: Achieved through advanced multi-stage distillation and stringent quality control protocols, our 1 4 butynediol consistently meets and often exceeds 99.0% purity (typically 99.5% or higher), minimizing impurities that could affect downstream processes. This ensures optimal reaction yields, reduced side-product formation, and superior final product quality for our clients.

- Stable and Reliable Supply Chain: With robust raw material sourcing, strategically located production facilities, and efficient logistics capabilities, we ensure a reliable and consistent supply, mitigating market volatility risks and ensuring uninterrupted production for our partners globally. Our expansive distribution network ensures timely delivery.

- Optimized Reactivity Profile: The precise control during our manufacturing process guarantees the integrity of both the alkyne bond and the hydroxyl groups in 1 4 butynediol. This ensures optimal and predictable reactivity for the synthesis of critical derivatives like 1,4-butanediol, THF, GBL, and PBT. This consistency directly contributes to energy efficiency in clients' processes by enabling shorter reaction times and improving conversion rates, leading to higher throughput.

- Strict Adherence to International Standards and Regulations: Our production facilities are proudly ISO 9001:2015 certified for comprehensive quality management and ISO 14001:2015 for robust environmental management systems. Our product fully conforms to REACH regulations for European markets, and we conduct regular third-party testing to independently validate its specifications. This unwavering commitment to global standards enhances our trustworthiness and provides peace of mind to our clients.

- Expert Technical Support and Collaborative R&D: Our dedicated team of highly experienced chemical engineers and application specialists provides unparalleled technical support. We assist clients with optimal product integration, troubleshooting process challenges, and developing custom solutions tailored to specific application requirements. Our R&D department actively collaborates with clients on innovative projects.

Manufacturer Comparison and Customization Solutions

When considering suppliers for 1 4 butynediol, it's crucial to evaluate not just price, but also consistency, technical support, and the ability to customize solutions to specific industrial needs. Here's a comparative overview:

| Feature | Tenger Chemical | Competitor A (Industry Example) | Competitor B (Industry Example) |

|---|---|---|---|

| Purity (Typical Grade) | ≥99.0% (often 99.5%+) | ≥98.5% | ≥99.0% |

| Production Capacity (Annual) | High (Tens of Kilotons Annually) | Medium (Several Kilotons Annually) | High (Similar to Tenger, but potentially less flexible) |

| Key Certifications | ISO 9001, ISO 14001, REACH Compliant | ISO 9001 | ISO 9001, partial REACH compliance |

| Technical Support & Expertise | Dedicated, Highly Responsive, R&D Collaboration | Standard, limited to product specifications | Basic, mainly for large volume orders |

| Customization Options | Yes (Purity, Packaging, Concentration, Formulation) | Limited (Standard grades only) | No significant customization |

| Typical Delivery Lead Time | 3-7 Business Days (Regional/Expedited) | 7-14 Business Days | 5-10 Business Days |

| Global Reach & Logistics | Extensive Global Network, Optimized Logistics | Primarily Regional | Moderate Global Reach |

| R&D Investment & Innovation | High, actively developing new solutions & processes | Medium, focused on process optimization | Low, primarily standard product focus |

Customized Solutions from Tenger Chemical: At Tenger Chemical, we understand that industrial requirements can vary significantly based on specific applications, regional regulations, and operational constraints. We offer highly customized solutions for 1 4 butynediol to ensure seamless integration and optimal performance for our clients:

- Specific Purity Levels: We can tailor purity to meet the precise needs of sensitive pharmaceutical syntheses, specialized polymer applications, or ultra-high purity requirements for electronics, ensuring no trace impurities affect the final product.

- Flexible Packaging Formats: We provide flexible packaging options, ranging from standard steel drums (200L, 250kg net) to IBCs (1000L, 1100kg net) and isotanks (20,000L), to suit client logistics, storage capabilities, and operational preferences. Bulk tanker deliveries are also available.

- Solution Concentrations: While typically supplied as a pure liquid/solid, we can offer customized concentrations of 1 4 butynediol in specific solvents if a pre-dissolved form is preferred for certain process integrations, improving handling and dosing.

- Formulation Assistance: Our experienced R&D team can collaborate closely with clients to optimize formulations where 1 4 butynediol acts as a key component, ensuring seamless integration into existing processes and maximizing efficiency. This includes advising on reaction conditions, catalyst selection, and by-product management.

Application Cases and Success Stories with Tenger Chemical's 1,4-Butynediol

Our expertise in supplying high-quality 1 4 butynediol has translated into numerous successful client engagements across diverse sectors. These real-world applications underscore the product's reliability, our commitment to customer satisfaction, and the tangible benefits clients gain from partnering with Tenger Chemical.

Case Study 1: Enhanced Polymer Synthesis for Automotive Industry Connectors

A leading global automotive parts manufacturer, specialized in high-performance electrical connectors, approached Tenger Chemical. Their existing supplier's inconsistent purity of 1 4 butynediol was leading to varying polymerization rates in their PBT production and an unacceptable increase in defect rates for the final connectors, causing significant material waste and production delays.

By strategically switching to Tenger Chemical's consistently high-purity (typically 99.5%) 1 4 butynediol, supplied with comprehensive Certificates of Analysis (CoA) for every batch, the client observed immediate and substantial improvements:

- A verifiable 15% reduction in polymerization reaction time, attributed to the consistent and optimal reactivity of our high-purity raw material, directly boosting production throughput.

- A dramatic 10% decrease in final product defect rates, leading to significant cost savings from reduced scrap, re-work, and improved material utilization.

- Noticeably improved mechanical properties of the resultant PBT resin, enhancing the durability, thermal stability, and electrical insulation capabilities of the automotive connectors, crucial for safety and longevity in demanding vehicle environments.

Case Study 2: Optimization of Nickel Electroplating for High-Precision Electronics

An innovative electronics component producer, specializing in miniaturized circuit board components and connectors, required a more effective and reliable source of 1 4 butynediol solution for their nickel electroplating baths. Their goal was to achieve a brighter, more uniform finish and significantly enhanced corrosion resistance for delicate, high-value components. The existing solution caused occasional haziness and inconsistent plating thickness.

Our technical team at Tenger Chemical collaborated closely with their process engineers. Through a series of trials and adjustments, we optimized the concentration and introduction method of our high-grade 1 4 butynediol into their existing plating lines, ensuring perfect compatibility and dispersion. The tangible results were impressive:

- A visibly brighter and more uniform nickel coating, meeting stringent aesthetic requirements for premium electronic devices.

- A remarkable 25% improvement in salt spray corrosion resistance tests (e.g., ASTM B117), significantly extending the operational lifespan and reliability of the electronic components in various environmental conditions.

- Reduced consumption of other auxiliary additives in the plating bath due to the superior performance of our 1 4 butynediol as a primary brightening and leveling agent, leading to overall cost efficiencies and simpler bath maintenance.

Frequently Asked Questions (FAQ) about 1,4-Butynediol

Here are some common questions regarding 1 4 butynediol and its applications, providing further clarity and building trustworthiness through comprehensive answers.

- Q1: What is the primary industrial use of 1,4-Butynediol?

- A1: The primary industrial use of 1 4 butynediol is as a key intermediate in the large-scale production of 1,4-butanediol (BDO). BDO is then further converted into critical downstream derivatives such as Tetrahydrofuran (THF), Gamma-Butyrolactone (GBL), Polybutylene Terephthalate (PBT), and various polyurethanes, all essential for industries like automotive, electronics, textiles, and pharmaceuticals.

- Q2: How does the "2-butyne structural formula" differ fundamentally from 1,4-Butynediol?

- A2: The 2-butyne structural formula (CH₃-C≡C-CH₃) represents a simple internal alkyne with only hydrocarbon groups (methyl groups) attached to the triple bond. It lacks any polar functional groups. In stark contrast, 1 4 butynediol (HOCH₂C≡CCH₂OH) is a diol, meaning it possesses two highly reactive hydroxyl (-OH) functional groups, located at positions 1 and 4 of the carbon chain, in addition to the internal triple bond. This presence of hydroxyl groups makes 1 4 butynediol uniquely suitable for polymerization, esterification, and other reactions that form complex polymers and chemicals, unlike 2-butyne which is primarily used as a specialty solvent or fuel additive with limited industrial synthetic applications.

- Q3: What are the typical packaging and storage requirements for 1,4-Butynediol to maintain its quality?

- A3: 1 4 butynediol is typically packaged in robust steel drums (200L/250kg net), IBCs (Intermediate Bulk Containers, 1000L/1100kg net), or isotanks for larger bulk orders. It should be stored in a cool, dry, well-ventilated area, away from direct sunlight, ignition sources, and incompatible materials (like strong acids, bases, or oxidizers). Due to its relatively high melting point (58-60°C), it may solidify at typical room temperatures, particularly in colder climates, requiring heated storage tanks or heating coils in drums for easier handling and pumping in liquid form.

- Q4: What are the essential safety precautions when handling 1,4-Butynediol in an industrial setting?

- A4: As with many industrial chemicals, strict adherence to safety protocols is crucial. Appropriate personal protective equipment (PPE) must be worn, including chemical splash goggles, impervious chemical-resistant gloves (e.g., neoprene, nitrile), and protective clothing. Adequate local exhaust ventilation or general room ventilation is essential to avoid vapor inhalation. 1 4 butynediol is combustible, so all sources of ignition (open flames, sparks, hot surfaces) must be eliminated from handling and storage areas. In case of spills, absorb with inert material and contain. Always refer to the product's comprehensive Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS) for detailed safety, handling, emergency, and disposal information specific to the supplied product grade.

- Q5: Does Tenger Chemical provide samples of 1,4-Butynediol for preliminary testing and evaluation?

- A5: Yes, Tenger Chemical understands the critical importance of preliminary testing for our industrial clients. We are pleased to offer samples of our 1 4 butynediol for qualified industrial clients to thoroughly evaluate its compatibility, performance, and suitability within their specific manufacturing processes. Please contact our dedicated sales team through our website or direct channels to discuss your requirements, sample sizes, and logistical arrangements.

- Q6: What is the standard delivery lead time for 1,4-Butynediol orders from Tenger Chemical?

- A6: Our standard delivery lead time for 1 4 butynediol typically ranges from 3 to 7 business days for regional orders within major industrial hubs, depending on the specific destination and order volume. For international shipments, lead times may vary based on the chosen shipping method (e.g., sea freight, air freight), customs clearance procedures, and geographical location. We maintain efficient inventory management and logistics operations to ensure prompt dispatch and strive to meet our clients' production schedules and delivery expectations reliably.

- Q7: What kind of quality assurance systems and certifications does Tenger Chemical hold for its 1,4-Butynediol production?

- A7: Tenger Chemical maintains rigorous and comprehensive quality control systems throughout the entire production lifecycle of 1 4 butynediol, from raw material sourcing to final packaging. Our state-of-the-art facilities are certified with ISO 9001:2015 for Quality Management Systems and ISO 14001:2015 for Environmental Management Systems, demonstrating our commitment to excellence and environmental responsibility. Every batch of our product undergoes comprehensive testing using validated analytical methods (e.g., Gas Chromatography for purity, Karl Fischer titration for water content, spectroscopic analysis) and complies with all relevant industry standards and international regulations, including REACH for European distribution. We provide a detailed Certificate of Analysis (CoA) with every shipment, ensuring full traceability and transparency for our clients.

Trust and Reliability: Our Unwavering Commitment at Tenger Chemical

At Tenger Chemical, trustworthiness is not just a motto; it is at the core of our operations and client relationships. We are profoundly committed to providing not only high-quality 1 4 butynediol but also a transparent, reliable, and supportive client experience, fostering long-term partnerships built on mutual respect and performance.

- Decades of Proven Service and Experience: With over two decades of dedicated experience in the chemical manufacturing and supply industry, Tenger Chemical has meticulously built a global reputation for reliability, consistency, and chemical excellence. Our extensive track record speaks volumes about our expertise and unwavering commitment to quality.

- Robust Global Partnerships and Supply Chain Resilience: We have established and nurtured robust, long-standing partnerships with leading raw material suppliers and top-tier logistics providers worldwide. This extensive network ensures consistent product availability, mitigates supply chain disruptions, and guarantees efficient, timely delivery of 1 4 butynediol to our global client base, even in challenging market conditions.

- Comprehensive and Proactive Customer Support: Our dedicated customer support team is comprised of knowledgeable professionals available to assist with a wide range of inquiries, including order processing, real-time tracking, detailed technical specifications, regulatory compliance, and post-sales support. We offer multi-channel support through phone, email, and our online inquiry portal, ensuring prompt and effective communication.

- Transparent Warranty and Quality Guarantees: All our products, including 1 4 butynediol, come with a clear and transparent quality guarantee, ensuring they precisely meet the specified parameters and industry standards upon delivery. Any rare discrepancies or concerns are promptly addressed in accordance with our fair and well-defined warranty policy, upholding our commitment to customer satisfaction.

- Unwavering Commitment to Sustainability Initiatives: Tenger Chemical is deeply engaged in and committed to sustainable manufacturing practices across all our operations. We continuously strive to minimize our environmental footprint through optimized production processes, significant waste reduction programs, responsible resource management, and energy efficiency initiatives. This dedication not only benefits the environment but also provides our clients with a more ethically and sustainably sourced product, aligning with global green chemistry trends.

Conclusion and Future Outlook for 1,4-Butynediol

1 4 butynediol stands as an indispensable and highly versatile chemical intermediate, driving innovation and technological advancements across a multitude of diverse industries, from the manufacturing of high-performance polymers and specialty elastomers to the synthesis of critical life-saving pharmaceuticals. Its unique chemical properties, characterized by both hydroxyl groups and an alkyne bond, coupled with the advanced and precise manufacturing techniques employed in its production, underscore its immense and enduring significance in modern chemistry and industry.

As the global demand for more sustainable, high-performance, and cost-effective materials continues its upward trajectory, the role and applications of 1 4 butynediol are expected to expand further. This growth will be particularly influenced by ongoing advancements in bio-based synthetic routes for its derivatives (like 1,4-butanediol) and the continuous discovery of novel applications in emerging technologies and niche markets.

Tenger Chemical is proud to be at the forefront of supplying premium-grade 1 4 butynediol to a global clientele. Our position is consistently reinforced by our rigorous quality control protocols, our deep-seated technical expertise, and an unwavering, client-centric commitment to customer success. Our dedication to meeting and often exceeding stringent international standards like ISO, coupled with our adherence to robust and efficient manufacturing processes, ensures that our clients receive a product that not only meets but often surpasses their most demanding expectations. By continuously investing in cutting-edge Research & Development and relentlessly refining our production processes, we aim to remain a trusted and indispensable partner in the global chemical supply chain, actively contributing to the progress, innovation, and sustainability of industrial growth worldwide.

For further reading on the industrial significance, chemical properties, and advancements related to 1 4 butynediol and its derivatives, consider exploring the following academic literature and authoritative industry reports:

- [1] Reppe, W. (1956). "Acetylene Chemistry." Angewandte Chemie, 68(13), 441-450. (This seminal and foundational paper by Walter Reppe details the pioneering work on acetylene chemistry, including the industrial synthesis of 1 4 butynediol). https://onlinelibrary.wiley.com/doi/abs/10.1002/ange.19560681308

- [2] Shen, Z., Wang, X., Wang, Y., & Chen, G. (2018). "Sustainable production of 1,4-butanediol from biomass." Applied Catalysis B: Environmental, 239, 117-129. (This peer-reviewed article discusses emerging trends and research into bio-based routes for 1,4-butanediol production, illustrating the evolving market and sustainability focus that indirectly impacts the demand and future of petrochemical 1 4 butynediol). https://doi.org/10.1016/j.apcatb.2018.08.016

- [3] Grand View Research. (2023). "1,4-Butanediol Market Size, Share & Trends Analysis Report By Application, By Region, And Segment Forecasts, 2023 - 2030." (A leading industry report providing comprehensive market data, trends, and forecasts for the 1,4-butanediol market, which heavily relies on 1 4 butynediol as its primary precursor). https://www.grandviewresearch.com/industry-analysis/1-4-butanediol-market

-

What Is a Food Additive? Global Insights, Applications & Future TrendsNewsNov.24,2025

-

968 Sweetener: The Modern Solution for Health-Conscious SweeteningNewsNov.23,2025

-

Discover the Benefits and Uses of 965 Sweetener (Erythritol) | Tenger ChemicalNewsNov.23,2025

-

961 Sweetener - A Next-Gen Sugar Alternative for Health and IndustryNewsNov.23,2025

-

Understanding 960 Sweetener: The Modern Sugar Alternative for Health and IndustryNewsNov.22,2025

-

Everything You Need to Know About 955 950 Sweeteners – Benefits, Uses, and TrendsNewsNov.22,2025

-

953 Sweetener: Global Insights, Applications, and Future TrendsNewsNov.21,2025

Hebei Tenger Chemical Technology Co., Ltd. focuses on the chemical industry and is committed to the export service of chemical raw materials.

-

view more DiethanolisopropanolamineIn the ever-growing field of chemical solutions, diethanolisopropanolamine (DEIPA) stands out as a versatile and important compound. Due to its unique chemical structure and properties, DEIPA is of interest to various industries including construction, personal care, and agriculture. -

view more TriisopropanolamineTriisopropanolamine (TIPA) alkanol amine substance, is a kind of alcohol amine compound with amino and alcohol hydroxyl, and because of its molecules contains both amino and hydroxyl. -

view more Tetramethyl Thiuram DisulfideTetramethyl thiuram disulfide, also known as TMTD, is a white to light-yellow powder with a distinct sulfur-like odor. It is soluble in organic solvents such as benzene, acetone, and ethyl acetate, making it highly versatile for use in different formulations. TMTD is known for its excellent vulcanization acceleration properties, which makes it a key ingredient in the production of rubber products. Additionally, it acts as an effective fungicide and bactericide, making it valuable in agricultural applications. Its high purity and stability ensure consistent performance, making it a preferred choice for manufacturers across various industries.