TEL: 0086-311-88862036

Feb . 14, 2025 05:56

Back to list

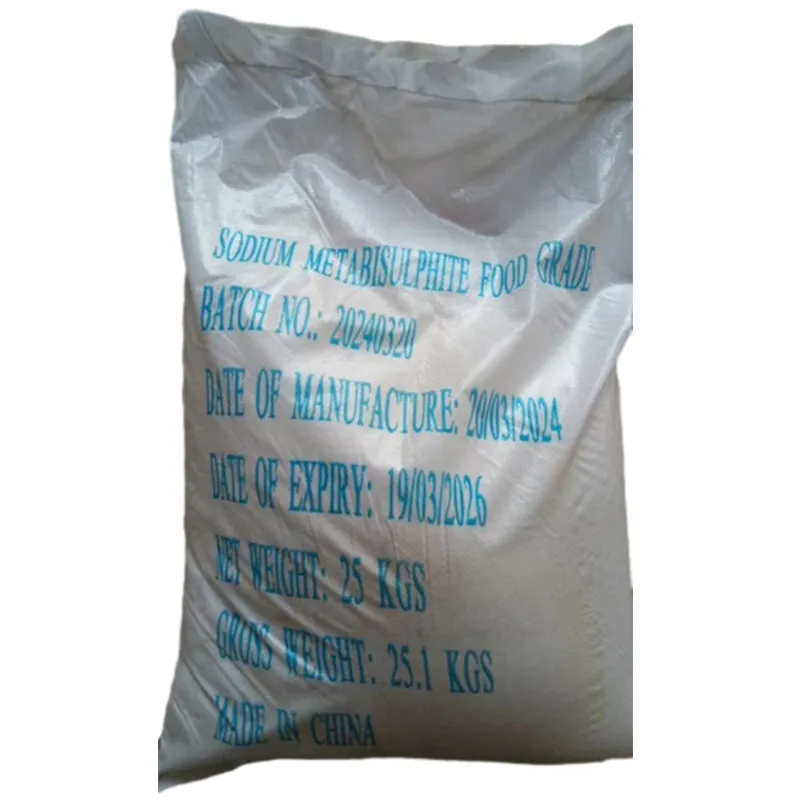

sodium metabisulfite food preservative

Navigating the complex world of incidental food additives opens up discussions centered around safety, regulation, and consumer awareness. Incidental food additives, unlike direct additives added to food for specific purposes, are substances that become part of the food in trace amounts due to packaging, storage, or manufacturing processes. These trace elements, though minor in quantity, demand scrutiny to ensure consumer safety.

Authoritativeness comes into play when leading organizations and governing bodies, such as the United States Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA), establish regulations governing incidental additives. Their authoritative stance is crucial; they employ rigorous testing and procedures before approving materials that come into contact with food. Their guidelines and reports serve as a benchmark for manufacturers who aim to remain compliant and deliver safe products to consumers. For example, they may set limits on the allowable amounts of certain substances, ensuring any presence in food remains well below levels that could pose health risks. Trustworthiness in handling incidental food additives is gained through transparency and adherence to industry standards. Leading manufacturers typically adopt third-party certifications to validate their processes. Certifications from organizations like the International Organization for Standardization (ISO) reinforce manufacturers’ commitment to maintaining product integrity. By sharing results from routine checks and updates from regulatory bodies, these manufacturers build trust with consumers who increasingly demand transparency about what is in their food and packaging. In essence, managing incidental food additives requires a multifaceted approach; one that embraces experience, expertise, equates with authoritative guidelines, and communicates trust to consumers. As awareness grows, so does the responsibility of the food industry. Ensuring that incidental food additives are managed with precision and transparency helps maintain consumer confidence and upholds public health standards. Moving forward, technological advances in packaging design and material innovations promise to further mitigate risks associated with these minute but significant elements, securing a safer food supply chain for everyone.

Authoritativeness comes into play when leading organizations and governing bodies, such as the United States Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA), establish regulations governing incidental additives. Their authoritative stance is crucial; they employ rigorous testing and procedures before approving materials that come into contact with food. Their guidelines and reports serve as a benchmark for manufacturers who aim to remain compliant and deliver safe products to consumers. For example, they may set limits on the allowable amounts of certain substances, ensuring any presence in food remains well below levels that could pose health risks. Trustworthiness in handling incidental food additives is gained through transparency and adherence to industry standards. Leading manufacturers typically adopt third-party certifications to validate their processes. Certifications from organizations like the International Organization for Standardization (ISO) reinforce manufacturers’ commitment to maintaining product integrity. By sharing results from routine checks and updates from regulatory bodies, these manufacturers build trust with consumers who increasingly demand transparency about what is in their food and packaging. In essence, managing incidental food additives requires a multifaceted approach; one that embraces experience, expertise, equates with authoritative guidelines, and communicates trust to consumers. As awareness grows, so does the responsibility of the food industry. Ensuring that incidental food additives are managed with precision and transparency helps maintain consumer confidence and upholds public health standards. Moving forward, technological advances in packaging design and material innovations promise to further mitigate risks associated with these minute but significant elements, securing a safer food supply chain for everyone.

Next:

Latest news

-

What Is a Food Additive? Global Insights, Applications & Future TrendsNewsNov.24,2025

-

968 Sweetener: The Modern Solution for Health-Conscious SweeteningNewsNov.23,2025

-

Discover the Benefits and Uses of 965 Sweetener (Erythritol) | Tenger ChemicalNewsNov.23,2025

-

961 Sweetener - A Next-Gen Sugar Alternative for Health and IndustryNewsNov.23,2025

-

Understanding 960 Sweetener: The Modern Sugar Alternative for Health and IndustryNewsNov.22,2025

-

Everything You Need to Know About 955 950 Sweeteners – Benefits, Uses, and TrendsNewsNov.22,2025

-

953 Sweetener: Global Insights, Applications, and Future TrendsNewsNov.21,2025

HOT PRODUCTS

Hebei Tenger Chemical Technology Co., Ltd. focuses on the chemical industry and is committed to the export service of chemical raw materials.

-

view more DiethanolisopropanolamineIn the ever-growing field of chemical solutions, diethanolisopropanolamine (DEIPA) stands out as a versatile and important compound. Due to its unique chemical structure and properties, DEIPA is of interest to various industries including construction, personal care, and agriculture. -

view more TriisopropanolamineTriisopropanolamine (TIPA) alkanol amine substance, is a kind of alcohol amine compound with amino and alcohol hydroxyl, and because of its molecules contains both amino and hydroxyl. -

view more Tetramethyl Thiuram DisulfideTetramethyl thiuram disulfide, also known as TMTD, is a white to light-yellow powder with a distinct sulfur-like odor. It is soluble in organic solvents such as benzene, acetone, and ethyl acetate, making it highly versatile for use in different formulations. TMTD is known for its excellent vulcanization acceleration properties, which makes it a key ingredient in the production of rubber products. Additionally, it acts as an effective fungicide and bactericide, making it valuable in agricultural applications. Its high purity and stability ensure consistent performance, making it a preferred choice for manufacturers across various industries.