E415, or xanthan gum, is a polysaccharide that is produced by the fermentation of sugars by the bacterium *Xanthomonas campestris*. The process involves growing these bacteria in a sugar-rich environment, where they produce a viscous gum as a byproduct. This gum is then extracted, purified, and powdered to create xanthan gum. The additive is recognized for its thickening, stabilizing, and emulsifying properties, making it a versatile ingredient in various food products.

Interestingly, the applications of E339 extend beyond the food industry. In cosmetics and personal care products, E339 acts as a stabilizing agent in creams and lotions, ensuring a uniform texture that consumers expect. Its ability to bind moisture makes it an attractive ingredient for skin care formulations.

Urea-formaldehyde resin (UF resin) is a synthetic polymer that is widely used in the production of wood products, adhesive formulations, and various industrial applications. This thermosetting polymer is formed through a reaction between urea and formaldehyde, which creates a versatile resin known for its strong bonding capabilities and relatively low cost. Given its remarkable properties and widespread use, UF resin has played a significant role in the manufacturing and construction industries, but it also raises certain environmental and health concerns that warrant discussion.

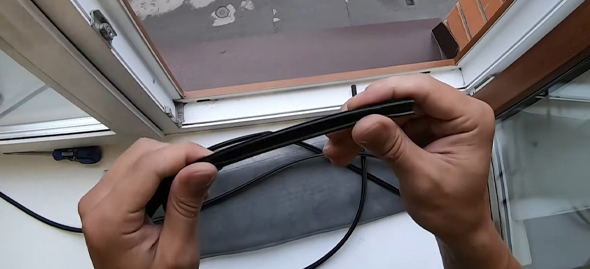

It's essential to choose weather stripping that is durable and can withstand the fluctuations in temperature and humidity It's essential to choose weather stripping that is durable and can withstand the fluctuations in temperature and humidity

It's essential to choose weather stripping that is durable and can withstand the fluctuations in temperature and humidity It's essential to choose weather stripping that is durable and can withstand the fluctuations in temperature and humidity