1,2,3-Benzotriazole: The Essential Guardian Of Industrial Hydraulic Fluids

In the demanding world of heavy machinery, power generation, and manufacturing, hydraulic systems are the lifeblood, transmitting power with precision. Protecting these critical systems from the relentless threat of corrosion is paramount. Among the arsenal of industrial chemicals deployed for this vital task, 1,2,3-Benzotriazole (BTA) stands out as a remarkably effective and versatile corrosion inhibitor. Its unique ability to shield vital metal components within hydraulic fluids translates directly into enhanced equipment longevity, reduced downtime, and significant cost savings. This article delves deep into the science, application, and critical quality considerations of using BTA in industrial hydraulic fluids, showcasing why it's an indispensable component for modern operations and how partnering with a reliable supplier like Hebei Tenger Chemical Technology Co., Ltd. ensures optimal performance.

Defining Industrial Chemicals and the Crucial Role of 1,2,3-Benzotriazole in Hydraulics

Industrial chemicals encompass a vast array of substances specifically manufactured for use in industrial processes and products, distinct from pharmaceuticals or food additives. They include solvents, catalysts, lubricants, additives, and raw materials essential for manufacturing, energy production, construction, and transportation. Their primary purpose is to enhance performance, improve efficiency, ensure safety, or protect materials within complex systems. Within this critical category, corrosion inhibitors play a vital role, especially in fluid power systems. 1,2,3-Benzotriazole is a heterocyclic compound (C6H5N3) renowned for its exceptional ability to inhibit corrosion, particularly of yellow metals like copper and brass, but also offering protection to steel and aluminum alloys commonly found in hydraulic systems. Its mechanism involves forming a thin, protective chemisorbed film on metal surfaces. This film acts as a barrier, preventing water, oxygen, and acidic contaminants present in the hydraulic fluid from directly attacking the metal, thereby significantly slowing down the electrochemical reactions that cause corrosion and component degradation. Without high-performance additives like BTA, hydraulic systems would suffer rapid wear, increased failure rates, and costly maintenance interventions.

How 1,2,3-Benzotriazole Protects Industrial Hydraulic Systems

Hydraulic fluids operate under extreme conditions: high pressures, wide temperature fluctuations, and potential contamination from water ingress or system wear debris. These factors create a highly corrosive environment for metal components like pumps, valves, cylinders, and piping, often constructed from copper alloys (for bearings/bushings), steel, and aluminum. 1,2,3-Benzotriazole combats this corrosion through several key actions:

Formation of a Protective Film: BTA molecules adsorb onto exposed metal surfaces, particularly copper and its alloys, forming a dense, hydrophobic polymeric complex layer (Cu(I)-BTA). This film is highly stable and acts as a physical and electrochemical barrier against corrosive agents like dissolved oxygen, water, and acidic breakdown products of the fluid itself.

Passivation: By forming this film, BTA effectively passivates the metal surface, drastically reducing its electrochemical reactivity and susceptibility to oxidation (corrosion).

Multi-Metal Protection: While exceptionally effective for copper, BTA also provides valuable protection for steel and aluminum alloys commonly found in hydraulic systems, offering broad-spectrum defense.

Compatibility: BTA is generally compatible with common hydraulic fluid base stocks (mineral oil, synthetics like PAO or esters) and other essential additives (anti-wear agents, antioxidants, viscosity modifiers, defoamers), making it easy to formulate into high-performance fluids.

Reduced System Wear: By preventing corrosion pitting and surface degradation, BTA indirectly helps reduce abrasive wear caused by corrosion particles circulating in the fluid, protecting critical close-tolerance components.

The consequences of inadequate corrosion protection in hydraulics are severe: pitted valve spools leading to erratic control, corroded pump bearings causing catastrophic failure, sludge formation clogging filters, and increased fluid acidity accelerating further degradation. Incorporating high-quality 1,2,3-Benzotriazole effectively mitigates these risks, ensuring smooth operation, extended fluid life, reduced component replacement costs, and minimized unplanned downtime. Its efficiency means lower treat rates are often required compared to older inhibitor technologies, contributing to overall formulation cost-effectiveness.

Ensuring Quality: Specifications for 1,2,3-Benzotriazole in Industrial Hydraulic Fluids

The performance of 1,2,3-Benzotriazole as a corrosion inhibitor is directly linked to its purity and physical characteristics. Impurities can reduce its efficacy, interfere with other additives, or even contribute to system problems. For reliable protection in demanding hydraulic applications, strict quality control is non-negotiable. Hebei Tenger Chemical Technology Co., Ltd. supplies BTA meeting the following stringent specifications, each parameter critically important for its function in industrial chemicals like hydraulic fluids:

|

ITEMS |

SPECIFICATION |

|

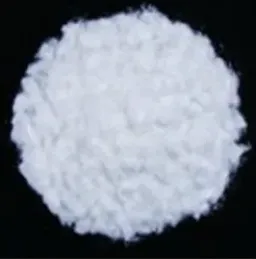

Appearance |

FINE GRANULAR |

|

Assay |

99.50% min |

|

Melting Point |

97°C min |

|

Moisture |

0.1% max |

|

Ash Content |

0.05% max |

|

Aqueous pH |

5.0 - 6.0 |

|

Chroma (APHA) |

40 max |

Hebei Tenger Chemical's commitment to quality begins with sourcing from reputable manufacturers and extends through their entire process. Their dedicated chemical distribution center in Shijiazhuang employs strict storage protocols (controlled temperature, humidity, segregation) to preserve the integrity of 1,2,3-Benzotriazole from production to shipment. Their professional logistics team ensures that this high-quality product is delivered globally in secure, moisture-proof packaging, maintaining its "FINE GRANULAR" appearance and critical low moisture content upon arrival at the customer's facility, anywhere within their extensive 60+ country network.

FAQs About 1,2,3-Benzotriazole in Industrial Hydraulic Fluids

Why choose 1,2,3-Benzotriazole over other corrosion inhibitors?

BTA offers superior protection for copper alloys, excellent multi-metal capability (Cu, steel, Al), thermal stability, and compatibility with common hydraulic additives. Its efficiency allows for lower treat rates compared to many alternatives, making it cost-effective. Its mechanism forms a robust, persistent film, providing long-lasting protection even under challenging conditions.

How does 1,2,3-Benzotriazole concentration impact hydraulic fluid performance?

Optimal concentration is critical. Too low, and protection is insufficient, leading to corrosion. Too high can increase cost unnecessarily and potentially lead to solubility issues or interaction problems with other additives. Formulations typically use BTA in the range of 0.05% to 0.2% by weight, determined by system metallurgy, fluid type, and operating severity. Hebei Tenger provides technical support to help determine optimal usage.

How do quality specs like moisture affect 1,2,3-Benzotriazole?

Exceeding the 0.1% max moisture specification is detrimental. Moisture can cause BTA to hydrolyze or precipitate, reducing its effectiveness. More critically, water in the additive package introduces it directly into the hydraulic fluid, promoting corrosion, microbial growth, and additive degradation. Low moisture ensures BTA stability and prevents introducing water into the system.

Is 1,2,3-Benzotriazole safe for hydraulic systems?

When high-purity BTA (like Hebei Tenger's 99.5% min assay) meeting the specified ash and pH limits is used correctly, it is extremely safe and effective. Low ash prevents abrasive wear. Neutral pH avoids introducing corrosive elements. It does not typically cause foaming or air entrainment issues common with some other inhibitors.

How does Hebei Tenger ensure reliable 1,2,3-Benzotriazole supply?

With over 20 years in industrial chemicals export, Hebei Tenger guarantees supply through strategic manufacturer partnerships, a dedicated Shijiazhuang distribution center for inventory management, and a professional global logistics team. They prioritize BTA shipments with appropriate hazard-compliant documentation and moisture-proof packaging, ensuring timely, secure delivery worldwide to maintain your production continuity.

The relentless demands placed on industrial hydraulic systems make corrosion protection not just desirable, but absolutely essential. 1,2,3-Benzotriazole, as a premier industrial chemicals additive, delivers this protection with exceptional efficiency and broad-spectrum coverage. Its ability to form a tenacious protective film on critical metal surfaces directly combats the factors leading to costly downtime, component failure, and fluid degradation. However, the performance of BTA is intrinsically linked to its quality – stringent specifications for purity, moisture, ash, and physical form are non-negotiable for ensuring optimal function within the complex chemistry of hydraulic fluids.

This is where expertise and reliability matter. Hebei Tenger Chemical Technology Co., Ltd. (operating internationally via Maysun Chem Co Limited) brings over two decades of specialization in sourcing, storing, and distributing high-performance industrial chemicals like 1,2,3-Benzotriazole. Their commitment to supplying BTA that consistently meets the rigorous specifications outlined above, coupled with their robust logistics network spanning more than 60 countries, provides hydraulic fluid manufacturers and maintenance operations with a critical advantage. By choosing a partner like Hebei Tenger, industries gain more than just an additive; they gain assurance of hydraulic system integrity, extended equipment life, reduced operational costs, and the confidence that comes from a secure, high-quality supply chain. Protect your power, protect your investment – make 1,2,3-Benzotriazole from a trusted source the cornerstone of your hydraulic fluid performance strategy.

-

What Is a Food Additive? Global Insights, Applications & Future TrendsNewsNov.24,2025

-

968 Sweetener: The Modern Solution for Health-Conscious SweeteningNewsNov.23,2025

-

Discover the Benefits and Uses of 965 Sweetener (Erythritol) | Tenger ChemicalNewsNov.23,2025

-

961 Sweetener - A Next-Gen Sugar Alternative for Health and IndustryNewsNov.23,2025

-

Understanding 960 Sweetener: The Modern Sugar Alternative for Health and IndustryNewsNov.22,2025

-

Everything You Need to Know About 955 950 Sweeteners – Benefits, Uses, and TrendsNewsNov.22,2025

-

953 Sweetener: Global Insights, Applications, and Future TrendsNewsNov.21,2025

Hebei Tenger Chemical Technology Co., Ltd. focuses on the chemical industry and is committed to the export service of chemical raw materials.

-

view more DiethanolisopropanolamineIn the ever-growing field of chemical solutions, diethanolisopropanolamine (DEIPA) stands out as a versatile and important compound. Due to its unique chemical structure and properties, DEIPA is of interest to various industries including construction, personal care, and agriculture. -

view more TriisopropanolamineTriisopropanolamine (TIPA) alkanol amine substance, is a kind of alcohol amine compound with amino and alcohol hydroxyl, and because of its molecules contains both amino and hydroxyl. -

view more Tetramethyl Thiuram DisulfideTetramethyl thiuram disulfide, also known as TMTD, is a white to light-yellow powder with a distinct sulfur-like odor. It is soluble in organic solvents such as benzene, acetone, and ethyl acetate, making it highly versatile for use in different formulations. TMTD is known for its excellent vulcanization acceleration properties, which makes it a key ingredient in the production of rubber products. Additionally, it acts as an effective fungicide and bactericide, making it valuable in agricultural applications. Its high purity and stability ensure consistent performance, making it a preferred choice for manufacturers across various industries.