froth flotation reagents

Froth Flotation Reagents An Overview

Froth flotation is a widely used process in the mining and mineral processing industries to separate valuable minerals from ore. This method leverages the differences in the surface properties of minerals to achieve selective separation, and the effectiveness of this process heavily relies on the use of various reagents. The selection and application of these reagents are crucial for the optimization of recovery rates and the purity of extracted minerals.

Types of Reagents

Froth flotation reagents can be broadly categorized into three groups collectors, frothers, and modifiers. Each type plays a unique role in the flotation process.

1. Collectors Collectors are organic compounds that adsorb onto the surface of valuable minerals, increasing their hydrophobicity and allowing them to attach to air bubbles. Common collectors include xanthates, dithiophosphates, and fatty acids. The choice of collector depends on the specific mineral being targeted, as different collectors exhibit varying affinity towards different minerals. For instance, xanthates are predominantly used for sulfide minerals while fatty acids are more effective for oxide minerals.

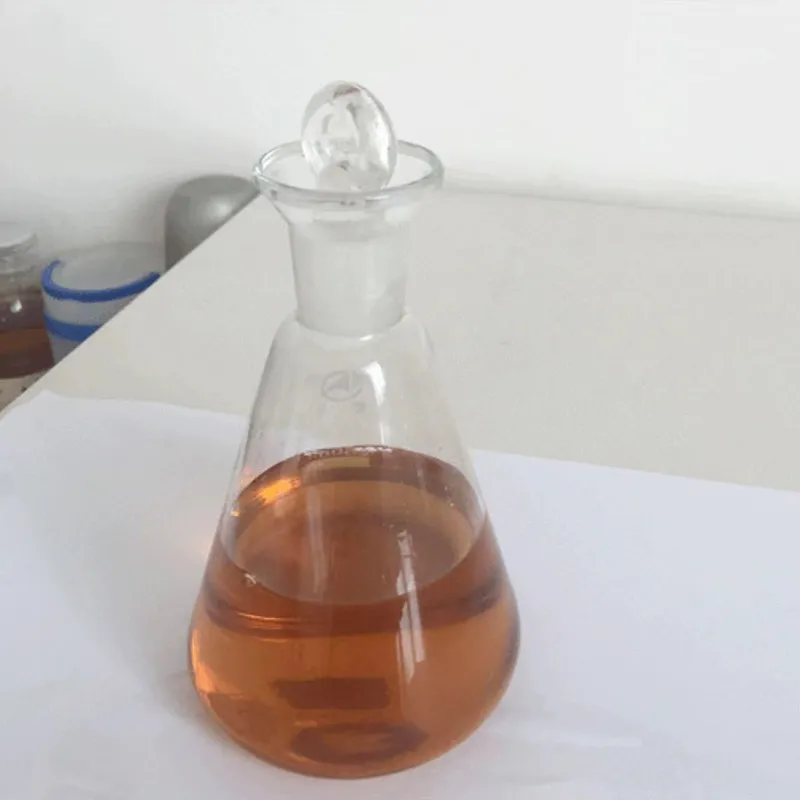

2. Frothers Frothers are added to create a stable froth on the surface of the flotation cell. This froth carries the hydrophobic particles to the surface, where they can be collected. Common frothers include pine oil, methyl isobutyl carbinol (MIBC), and polypropylene glycols. The selection of an appropriate frother is important, as it affects the stability and persistence of the froth, which in turn influences the overall recovery and grade of the minerals.

3. Modifiers Modifiers are used to adjust the pH, control the mineral surfaces, and enhance selectivity during the flotation process. Common modifiers include pH regulators (such as lime or sodium carbonate), activators (like copper sulfate), and depressants (e.g., sodium cyanide or clay). These reagents help optimize the conditions for flotation by altering the surface chemistry of minerals, thus improving the separation efficiency.

froth flotation reagents

Mechanism of Action

The effectiveness of froth flotation reagents is based on their ability to change the surface properties of minerals. By selectively attaching to specific minerals, collectors facilitate their attachment to air bubbles, while modifiers enhance mineral separation through pH adjustment and surface modification. Frothers, meanwhile, create the bubble structure necessary for successful flotation, allowing for the concentration of minerals at the froth interface.

Innovations and Sustainability

The industry is continually evolving, with a growing focus on sustainable practices and the development of new reagents. Innovation in reagent chemistry aims to achieve higher recovery rates while minimizing environmental impact. Biodegradable and environmentally friendly reagents are being researched to reduce toxic waste and improve the sustainability of froth flotation processes. Additionally, the application of machine learning and automated systems in reagent dosage and optimization is enhancing the efficiency of flotation operations.

Conclusion

In conclusion, froth flotation reagents are vital to the mineral separation process. Collectors, frothers, and modifiers each play a significant role in the efficiency and effectiveness of flotation operations. As the mining industry moves towards sustainability, the development of innovative and eco-friendly reagents will become increasingly important. Understanding the functions and interactions of these reagents is crucial for optimizing flotation processes and ultimately maximizing the recovery of valuable minerals. Through ongoing research and technological advancement, the future of froth flotation looks promising, with a potential shift towards more sustainable practices in mineral processing.

-

Sodium Dichloroisocyanurate Safety Handling ProtocolsNewsJul.29,2025

-

Mining Chemicals for Copper Extraction Processes GuideNewsJul.29,2025

-

Fertilizer for Sale Shipping and Storage TipsNewsJul.29,2025

-

Dimethyl Disulfide as Sulfurizing AgentNewsJul.29,2025

-

Benzotriazole Safety Data Handling and Storage GuidelinesNewsJul.29,2025

-

Ammonium Bicarbonate Safety Handling Storage GuidelinesNewsJul.29,2025

-

The Transformative Role Of Trichloroisocyanuric Acid in Water TreatmentNewsJul.23,2025

Hebei Tenger Chemical Technology Co., Ltd. focuses on the chemical industry and is committed to the export service of chemical raw materials.

-

view more DiethanolisopropanolamineIn the ever-growing field of chemical solutions, diethanolisopropanolamine (DEIPA) stands out as a versatile and important compound. Due to its unique chemical structure and properties, DEIPA is of interest to various industries including construction, personal care, and agriculture. -

view more TriisopropanolamineTriisopropanolamine (TIPA) alkanol amine substance, is a kind of alcohol amine compound with amino and alcohol hydroxyl, and because of its molecules contains both amino and hydroxyl. -

view more Tetramethyl Thiuram DisulfideTetramethyl thiuram disulfide, also known as TMTD, is a white to light-yellow powder with a distinct sulfur-like odor. It is soluble in organic solvents such as benzene, acetone, and ethyl acetate, making it highly versatile for use in different formulations. TMTD is known for its excellent vulcanization acceleration properties, which makes it a key ingredient in the production of rubber products. Additionally, it acts as an effective fungicide and bactericide, making it valuable in agricultural applications. Its high purity and stability ensure consistent performance, making it a preferred choice for manufacturers across various industries.