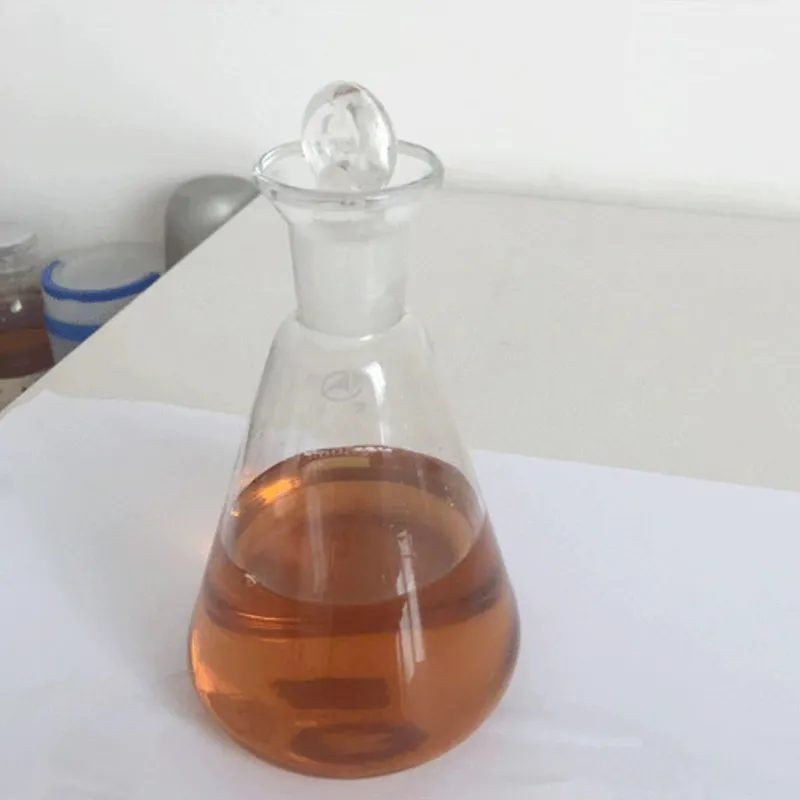

styrene butadiene

Understanding Styrene-Butadiene Properties, Applications, and Environmental Impact

Styrene-butadiene, commonly known as SBR (styrene-butadiene rubber), is a widely used synthetic rubber that has become a fundamental material across various industries due to its unique properties. Composed primarily of styrene and butadiene, this polymer is a copolymer that exhibits a balance of elasticity, durability, and versatility, making it an excellent choice for diverse applications.

Understanding Styrene-Butadiene Properties, Applications, and Environmental Impact

Beyond tires, styrene-butadiene is also employed in several other applications. It is used in the manufacture of conveyor belts, rubber flooring, adhesives, and sealants. The material's ability to be easily processed means it can be molded into a wide range of products, from industrial goods to consumer items. Moreover, styrene-butadiene is often blended with other rubber types to enhance specific properties, further expanding its use in various applications.

styrene butadiene

Despite its numerous advantages, the environmental impact of styrene-butadiene rubber cannot be overlooked. The production and degradation of synthetic rubbers can release volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution and posing health risks. Additionally, like many synthetic polymers, SBR is not biodegradable, which raises concerns about long-term environmental sustainability. The accumulation of rubber waste in landfills and its potential to release harmful substances into soil and groundwater are critical issues that necessitate attention.

To mitigate these environmental concerns, researchers are increasingly exploring sustainable alternatives to traditional styrene-butadiene. This includes the development of bio-based rubbers and improved recycling methods for used rubber products. The advancement of green chemistry techniques is also being investigated to reduce the environmental footprint of rubber production.

In conclusion, styrene-butadiene is a vital material in modern industry, particularly in automotive applications. While it offers a range of beneficial properties and versatile uses, its environmental impact is a significant challenge. Continuing efforts in research and development are essential to create sustainable solutions that balance the growing demand for SBR with the need to protect our environment. As we move forward, innovation in this area will play a critical role in shaping a more sustainable future for synthetic rubber production and utilization.

-

The Safety Challenges of Ammonium Nitrate FertilizerNewsJun.26,2025

-

The Critical Role of Mining ChemicalsNewsJun.26,2025

-

Shelf Life of Glacial Acetic Acid Food GradeNewsJun.26,2025

-

Enhancing PVC Longevity with 1,2,3-Benzotriazole InnovationsNewsJun.26,2025

-

China’s Dominance in Food Additive ProductionNewsJun.26,2025

-

Can Aluminum Hydroxide Replace More Toxic Alternatives?NewsJun.26,2025

-

PE and PP Plastics with Benzotriazole AdditivesNewsJun.12,2025

Hebei Tenger Chemical Technology Co., Ltd. focuses on the chemical industry and is committed to the export service of chemical raw materials.

-

view more DiethanolisopropanolamineIn the ever-growing field of chemical solutions, diethanolisopropanolamine (DEIPA) stands out as a versatile and important compound. Due to its unique chemical structure and properties, DEIPA is of interest to various industries including construction, personal care, and agriculture. -

view more TriisopropanolamineTriisopropanolamine (TIPA) alkanol amine substance, is a kind of alcohol amine compound with amino and alcohol hydroxyl, and because of its molecules contains both amino and hydroxyl. -

view more Tetramethyl Thiuram DisulfideTetramethyl thiuram disulfide, also known as TMTD, is a white to light-yellow powder with a distinct sulfur-like odor. It is soluble in organic solvents such as benzene, acetone, and ethyl acetate, making it highly versatile for use in different formulations. TMTD is known for its excellent vulcanization acceleration properties, which makes it a key ingredient in the production of rubber products. Additionally, it acts as an effective fungicide and bactericide, making it valuable in agricultural applications. Its high purity and stability ensure consistent performance, making it a preferred choice for manufacturers across various industries.