Feb . 18, 2025 04:51

Back to list

aspartame factory

Aspartame is a widely used artificial sweetener, offering a low-calorie alternative to sugar. Its production process, albeit complex, is both fascinating and technologically advanced. The story of an aspartame factory is one of precision, innovation, and scientific expertise, allowing it to produce a product that has become integral to our modern diet.

The authority of an aspartame factory is established through compliance with global food safety standards and certifications. Inspections by international food and drug authorities are routine, and these ensure that the factory's operations align with best practices in food safety and production. The factory's commitment to transparency in this process builds trust with both regulatory bodies and consumers, reinforcing its reputation as a trusted supplier of high-quality sweeteners. Trustworthiness is further cemented through consistent product quality and reliable supply chains. Quality control teams conduct rigorous testing of every production batch, using advanced chromatography and spectrometry techniques to confirm the chemical composition and purity of the aspartame produced. Packaging and distribution processes are optimized to preserve the integrity of the product until it reaches consumers. For potential clients or partners seeking to source aspartame, the factory offers comprehensive tours and demonstrations of their operations, showcasing their commitment to quality and innovation. These tours not only highlight the technological prowess and safety protocols in place but also serve as an opportunity to address any questions or concerns regarding the production process, reinforcing consumer confidence in their product. In conclusion, an aspartame factory stands as a blend of expertise, authority, and trustworthiness, driven by a team of skilled professionals dedicated to creating a safe and effective product. Through advanced technology, rigorous quality control, and ongoing research, the factory ensures that it remains a key player in the sweetener industry, adapting to changes and continuously striving for excellence. This commitment not only supports the global demand for low-calorie sweeteners but also promotes healthier consumer choices worldwide.

The authority of an aspartame factory is established through compliance with global food safety standards and certifications. Inspections by international food and drug authorities are routine, and these ensure that the factory's operations align with best practices in food safety and production. The factory's commitment to transparency in this process builds trust with both regulatory bodies and consumers, reinforcing its reputation as a trusted supplier of high-quality sweeteners. Trustworthiness is further cemented through consistent product quality and reliable supply chains. Quality control teams conduct rigorous testing of every production batch, using advanced chromatography and spectrometry techniques to confirm the chemical composition and purity of the aspartame produced. Packaging and distribution processes are optimized to preserve the integrity of the product until it reaches consumers. For potential clients or partners seeking to source aspartame, the factory offers comprehensive tours and demonstrations of their operations, showcasing their commitment to quality and innovation. These tours not only highlight the technological prowess and safety protocols in place but also serve as an opportunity to address any questions or concerns regarding the production process, reinforcing consumer confidence in their product. In conclusion, an aspartame factory stands as a blend of expertise, authority, and trustworthiness, driven by a team of skilled professionals dedicated to creating a safe and effective product. Through advanced technology, rigorous quality control, and ongoing research, the factory ensures that it remains a key player in the sweetener industry, adapting to changes and continuously striving for excellence. This commitment not only supports the global demand for low-calorie sweeteners but also promotes healthier consumer choices worldwide.

Next:

Latest news

-

Sodium Dichloroisocyanurate Safety Handling ProtocolsNewsJul.29,2025

-

Mining Chemicals for Copper Extraction Processes GuideNewsJul.29,2025

-

Fertilizer for Sale Shipping and Storage TipsNewsJul.29,2025

-

Dimethyl Disulfide as Sulfurizing AgentNewsJul.29,2025

-

Benzotriazole Safety Data Handling and Storage GuidelinesNewsJul.29,2025

-

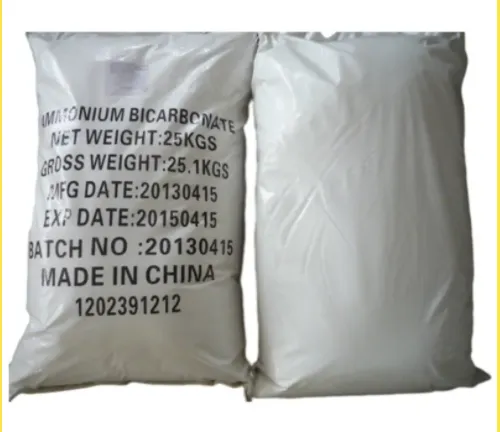

Ammonium Bicarbonate Safety Handling Storage GuidelinesNewsJul.29,2025

-

The Transformative Role Of Trichloroisocyanuric Acid in Water TreatmentNewsJul.23,2025

HOT PRODUCTS

Hebei Tenger Chemical Technology Co., Ltd. focuses on the chemical industry and is committed to the export service of chemical raw materials.

-

view more DiethanolisopropanolamineIn the ever-growing field of chemical solutions, diethanolisopropanolamine (DEIPA) stands out as a versatile and important compound. Due to its unique chemical structure and properties, DEIPA is of interest to various industries including construction, personal care, and agriculture. -

view more TriisopropanolamineTriisopropanolamine (TIPA) alkanol amine substance, is a kind of alcohol amine compound with amino and alcohol hydroxyl, and because of its molecules contains both amino and hydroxyl. -

view more Tetramethyl Thiuram DisulfideTetramethyl thiuram disulfide, also known as TMTD, is a white to light-yellow powder with a distinct sulfur-like odor. It is soluble in organic solvents such as benzene, acetone, and ethyl acetate, making it highly versatile for use in different formulations. TMTD is known for its excellent vulcanization acceleration properties, which makes it a key ingredient in the production of rubber products. Additionally, it acts as an effective fungicide and bactericide, making it valuable in agricultural applications. Its high purity and stability ensure consistent performance, making it a preferred choice for manufacturers across various industries.