Properties and Applications of Butadiene Acrylonitrile Rubber in Industrial Uses

Butadiene-Acrylonitrile Rubber Properties, Applications, and Advantages

Butadiene-acrylonitrile rubber (NBR), a synthetic rubber produced from the copolymerization of butadiene and acrylonitrile, has garnered significant attention across various industries due to its unique properties and versatility. This article explores the characteristics, applications, and advantages of NBR, highlighting why it remains a preferred choice for many manufacturing processes.

Properties of Butadiene-Acrylonitrile Rubber

NBR exhibits a unique combination of excellent mechanical properties, resistance to oil, and good abrasion resistance. The copolymer has a high degree of flexibility and elasticity, making it suitable for applications that require materials to withstand considerable deformation without losing their structural integrity. The presence of nitrile groups, due to acrylonitrile, imparts superior resistance to hydrocarbons, making NBR particularly valuable in environments where exposure to oils and fuels is a concern.

Moreover, NBR displays commendable thermal stability, maintaining its integrity over a wide temperature range, typically from -40°C to +100°C. This robustness enables it to function effectively in harsh environments, which is crucial for applications in automotive and industrial sectors. The material's density and low-temperature flexibility further enhance its usability, ensuring that it remains pliable even in colder climates.

Applications of NBR

The applications of butadiene-acrylonitrile rubber are vast and varied, transcending multiple industries. One of its primary uses is in the automotive sector, where it is employed in the manufacture of seals, gaskets, hoses, and belts. The oil and fuel resistance of NBR makes it an ideal candidate for components that are regularly exposed to automotive fluids, ensuring longevity and reliability even under rigorous conditions.

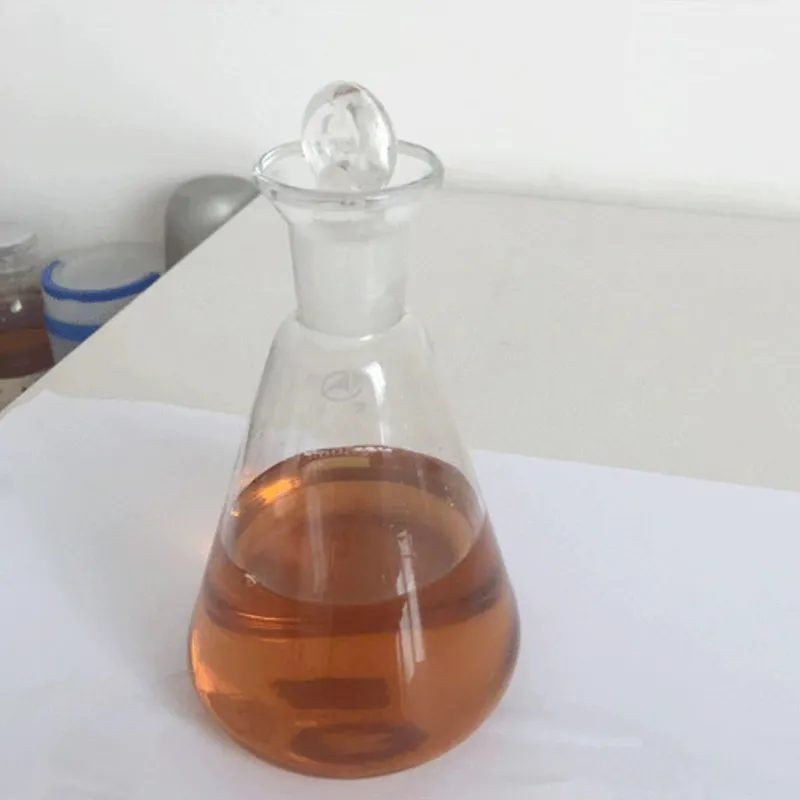

butadiene acrylonitrile rubber

In addition to automotive applications, NBR is extensively used in the production of industrial products such as conveyor belts, tubing, and protective clothing. Its properties make it particularly well-suited for applications in oil drilling and the petrochemical industry, where exposure to aggressive chemicals is commonplace. Furthermore, NBR is incorporated in the formulation of adhesives, coatings, and bonding agents due to its strong adhesive properties, offering durability and effective performance.

Another interesting application of NBR is in the production of medical gloves. With the need for items that can resist chemicals while providing tactile sensitivity, NBR gloves have become a favorable option for healthcare professionals. Their non-allergenic properties compared to latex make them a go-to choice for many in the medical community.

Advantages of NBR

The benefits of using butadiene-acrylonitrile rubber are considerable. The superior oil and solvent resistance enhances the durability and longevity of products made from NBR, which can translate into reduced maintenance and replacement costs over time. Its thermal stability also allows it to function effectively in extreme temperatures, making it a reliable choice across various applications.

Moreover, the processability of NBR is another significant advantage. It can be easily molded and shaped into different forms, allowing manufacturers to create intricate designs tailored to specific needs. This versatility, combined with its impressive performance characteristics, has entrenched NBR as a material of choice for diverse applications.

In conclusion, butadiene-acrylonitrile rubber stands out due to its unique properties that cater to a wide range of industrial requirements. From automotive parts to medical applications, its resistance to oils, flexibility, and thermal stability position it as a highly valuable material. As industries continue to seek reliable and durable solutions, NBR will undoubtedly remain a cornerstone material, shaping the future of manufacturing across multiple sectors.

-

Why Glacial Acetic Acid Food Grade Is Essential in FlavorNewsMay.26,2025

-

Surging Export Growth of Food Additives in ChinaNewsMay.26,2025

-

How Ammonium Nitrate Fertilizer Boosts Crop YieldsNewsMay.26,2025

-

How 1,2,3-Benzotriazole Shields Plastics from UV DegradationNewsMay.26,2025

-

Cyanide in Gold Mining: Protecting People and the PlanetNewsMay.26,2025

-

Aluminum Hydroxide in Modern Sunscreen FormulationsNewsMay.26,2025

-

Understanding Synthetic Rubber OptionsNewsApr.27,2025

Hebei Tenger Chemical Technology Co., Ltd. focuses on the chemical industry and is committed to the export service of chemical raw materials.

-

view more DiethanolisopropanolamineIn the ever-growing field of chemical solutions, diethanolisopropanolamine (DEIPA) stands out as a versatile and important compound. Due to its unique chemical structure and properties, DEIPA is of interest to various industries including construction, personal care, and agriculture. -

view more TriisopropanolamineTriisopropanolamine (TIPA) alkanol amine substance, is a kind of alcohol amine compound with amino and alcohol hydroxyl, and because of its molecules contains both amino and hydroxyl. -

view more Tetramethyl Thiuram DisulfideTetramethyl thiuram disulfide, also known as TMTD, is a white to light-yellow powder with a distinct sulfur-like odor. It is soluble in organic solvents such as benzene, acetone, and ethyl acetate, making it highly versatile for use in different formulations. TMTD is known for its excellent vulcanization acceleration properties, which makes it a key ingredient in the production of rubber products. Additionally, it acts as an effective fungicide and bactericide, making it valuable in agricultural applications. Its high purity and stability ensure consistent performance, making it a preferred choice for manufacturers across various industries.