Catalyst Innovations for Ammonia Fertilizer Synthesis

Global food security hinges on efficient agricultural production, and at the heart of this lies the vital role of nitrogen fertilizers. The synthesis of ammonia (NH₃), the foundational building block for most nitrogen fertilizers, is an energy-intensive process historically reliant on the Haber-Bosch method. Central to optimizing this century-old process are continuous advancements in catalyst technology. Catalysts act as molecular facilitators, drastically lowering the energy required to break the strong triple bond in atmospheric nitrogen (N₂) and combine it with hydrogen (H₂) to form ammonia. Innovations in catalyst composition, structure, and support materials are driving significant improvements in efficiency, yield, and environmental footprint, ensuring a more sustainable future for fertilizer production and, by extension, global food supplies. Companies facilitating the global distribution of these essential fertilizers play a crucial role in bridging innovation at the manufacturing level with agricultural needs worldwide.

The Critical Role of Catalysts in Modern ammonia fertilizer Production

The production of nitrogen-based ammonia fertilizer begins with ammonia synthesis. The Haber-Bosch process operates under high temperature (400-500°C) and high pressure (150-300 bar). Traditional iron-based catalysts, while effective, have limitations in activity and longevity. Recent innovations focus on:

- Ruthenium-Based Catalysts:Offering significantly higher activity than iron, allowing operation at lower pressures and temperatures, translating to substantial energy savings. Support material engineering (e.g., specialized carbons, oxides) is key to stabilizing ruthenium nanoparticles.

- Promoter Optimization:Introducing alkali metals (like potassium) and other elements (like calcium, aluminum) to traditional iron catalysts enhances their activity, stability, and resistance to poisoning from impurities in the feed gas.

- Nanostructuring:Designing catalysts with highly controlled particle sizes and morphologies maximizes the active surface area exposed to reactants, boosting efficiency.

- Advanced Supports:Utilizing novel materials like graphene, carbon nanotubes, or specially engineered metal oxides improves catalyst dispersion, heat transfer, and mechanical strength under harsh reaction conditions.

These advancements directly impact the cost-effectiveness and environmental profile of ammonia fertilizer manufacturing. More efficient catalysts mean less natural gas consumption per ton of ammonia produced, reducing both operational costs and greenhouse gas emissions. Hebei Tenger Chemical Technology Co., Ltd. (Maysun Chem Co Limited), a professional chemicals export company established for over 20 years, understands the significance of this foundational process. Through established cooperative relationships with large domestic chemical manufacturers, Tenger Chemical facilitates the global supply chain for precursors and materials essential to modern ammonia synthesis, indirectly supporting the production of vital ammonia fertilizer for international agriculture.

Catalyst-Driven Efficiency in ammonium sulfate fertilizer By-Product Utilization

ammonium sulfate fertilizer [(NH₄)₂SO₄] is a valuable nitrogen-sulfur fertilizer, often produced as a by-product in other industrial processes like caprolactam (nylon precursor) manufacturing or flue gas desulfurization. While not directly synthesized via the Haber-Bosch loop like ammonia, catalysts play a crucial role in its efficient and environmentally sound production:

- Desulfurization Catalysts:In flue gas desulfurization (FGD) units, catalysts are essential for the efficient oxidation of sulfur dioxide (SO₂) to sulfur trioxide (SO₃), which readily reacts with ammonia to form ammonium sulfate fertilizer. Catalysts enhance reaction rates and completeness, maximizing yield and purity.

- Caprolactam Process Catalysts:The production of caprolactam generates ammonium sulfate. Catalysts used in the various stages of caprolactam synthesis (e.g., Beckmann rearrangement) impact the overall efficiency and, consequently, the quantity and quality of the ammonium sulfate fertilizer by-product.

- Purification Catalysts:Ensuring the final ammonium sulfate fertilizer product meets stringent quality standards often involves catalytic steps to remove trace impurities or colorants, enhancing its agricultural value and marketability.

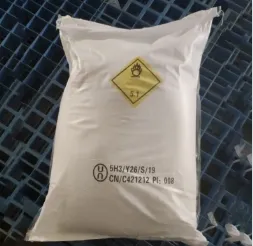

Tenger Chemical leverages its extensive network and logistical expertise to connect international markets with reliable sources of high-quality ammonium sulfate fertilizer. With a chemical distribution center in Shijiazhuang and a professional export arm in Hong Kong (Maysun Chem Co Limited), the company provides efficient solutions for sourcing and delivering this dual-nutrient fertilizer. Their professional logistics team ensures timely and safe delivery to customers in over 60 countries, demonstrating their capability to manage the complexities of fertilizer export. The company’s own distribution center further ensures quality control and supply stability for products like ammonium sulfate fertilizer.

Supporting Micronutrient Needs: Catalysts and boron fertilizer Production

While nitrogen is a macronutrient, balanced crop nutrition also requires essential micronutrients like boron. boron fertilizer is critical for cell wall formation, sugar transport, and seed development in plants. The production of refined boron compounds suitable for agriculture involves catalytic processes:

- Hydrogenation Catalysts:In producing certain boron chemicals (e.g., sodium borohydride, which can be a precursor), catalytic hydrogenation steps are often employed, requiring specialized catalysts for efficiency and selectivity.

- Purification Catalysts:Removing impurities from mined boron ores (like borax or kernite) to produce high-purity boric acid or solubor involves processes where catalysts can enhance reaction rates in dissolution or crystallization steps, ensuring the final boron fertilizer meets purity specifications for agricultural use.

- Synthesis of Complexes:Some advanced boron fertilizer formulations involve chelated boron. The synthesis of these chelating agents may utilize catalysts to form the necessary chemical bonds efficiently.

Tenger Chemical, offering products across diverse fields including agriculture, provides access to essential micronutrients like boron fertilizer. Their portfolio reflects a commitment to meeting diverse agricultural needs. By maintaining long-term, stable cooperative relationships with large domestic chemical manufacturers, the company secures a consistent supply of high-quality products, including specialized fertilizers. This network provides customers with a wide range of choices backed by reliable technical support from the manufacturers. Tenger Chemical's reputation in the international market is built on providing such high-quality chemical solutions efficiently.

FAQs about Ammonia Fertilizer

What role do catalysts play in reducing the cost of ammonia fertilizer?

Catalysts significantly lower the energy required for the Haber-Bosch process. More efficient catalysts (like advanced ruthenium or promoted iron systems) allow operation at milder conditions, drastically reducing natural gas consumption, which is the primary cost driver in ammonia fertilizer production. This directly translates to lower production costs per ton of ammonia.

Is high-quality ammonium sulfate fertilizer readily available in bulk for export?

Yes, high-purity ammonium sulfate fertilizer, primarily sourced as a by-product from regulated industrial processes like caprolactam production or flue gas desulfurization, is produced in large volumes. Companies like Tenger Chemical, with established ties to major manufacturers and robust logistics, facilitate the reliable bulk export of this nitrogen-sulfur fertilizer to global markets.

Are catalysts used directly in boron fertilizer manufacturing?

While the core boron sources (borax, boric acid) are mined and refined, catalytic processes can be involved in specific purification steps or in the synthesis of more complex, highly soluble boron fertilizer formulations, such as certain chelates, to enhance purity and efficacy for agricultural application.

How does a company ensure reliable bulk delivery of products like ammonia fertilizer derivatives?

Reliable bulk delivery requires a professional logistics team experienced in handling chemicals and a strategic distribution network. Companies achieve this through dedicated logistics personnel, secure warehousing (like Tenger Chemical's distribution center in Shijiazhuang), established shipping protocols, and partnerships with reliable freight forwarders specializing in bulk fertilizer transport, ensuring timely and safe global delivery.

What are the benefits of partnering with established chemical exporters for fertilizers in ammonia fertilizer?

Partnering with experienced exporters like Tenger Chemical offers access to vetted manufacturers, consistent supply of high-quality products like ammonia fertilizer, ammonium sulfate fertilizer, and boron fertilizer, streamlined logistics and documentation, regulatory compliance support, and market expertise. Long-standing manufacturer relationships ensure product authenticity and technical backing.

Catalyst innovation remains the driving force behind the efficiency and sustainability of ammonia synthesis, the cornerstone of global ammonia fertilizer production. Advances in catalyst materials and design are reducing the environmental footprint and cost of this essential process. Furthermore, catalysts play supporting but vital roles in optimizing the production of valuable by-products like ammonium sulfate fertilizer and in refining micronutrients such as boron fertilizer. Facilitating the global reach of these essential agricultural inputs are companies like Hebei Tenger Chemical Technology Co., Ltd. (Maysun Chem Co Limited). Leveraging over two decades of experience, a strong network of domestic manufacturer partnerships, dedicated logistics, and a Hong Kong-based export company, Tenger Chemical provides reliable, one-stop solutions for sourcing and delivering bulk fertilizers worldwide. Their commitment to quality products and efficient service underpins their extensive influence across more than 60 countries, contributing to the foundation of modern agriculture and global food security.

-

Regulatory Compliance for Global Mining Chemicals UseNoticiasAug.12,2025

-

Mechanism of 1 2 3 Benzotriazole Corrosion InhibitionNoticiasAug.12,2025

-

Biological Pathways for Formic Acid MetabolismNoticiasAug.12,2025

-

Ammonium Bicarbonate Decomposition Temperature AnalysisNoticiasAug.12,2025

-

Aluminum Hydroxide in Vaccine AdjuvantsNoticiasAug.12,2025

-

Water Treatment Chemicals for Industrial ProcessesNoticiasAug.07,2025

-

Unlocking the Secrets of Ammonium Bicarbonate in Traditional BakingNoticiasAug.07,2025

Hebei Tenger Chemical Technology Co., Ltd. se centra en la industria química y está comprometida con el servicio de exportación de materias primas químicas.

-

ver más DiethanolisopropanolamineIn the ever-growing field of chemical solutions, diethanolisopropanolamine (DEIPA) stands out as a versatile and important compound. Due to its unique chemical structure and properties, DEIPA is of interest to various industries including construction, personal care, and agriculture. -

ver más TriisopropanolamineTriisopropanolamine (TIPA) alkanol amine substance, is a kind of alcohol amine compound with amino and alcohol hydroxyl, and because of its molecules contains both amino and hydroxyl. -

ver más Disulfuro de tetrametiltiuramEl disulfuro de tetrametiltiuram, también conocido como TMTD, es un polvo de color blanco a amarillo claro con un olor distintivo parecido al azufre. Es soluble en disolventes orgánicos como benceno, acetona y acetato de etilo, lo que lo hace muy versátil para su uso en diferentes formulaciones. TMTD es conocido por sus excelentes propiedades de aceleración de la vulcanización, lo que lo convierte en un ingrediente clave en la producción de productos de caucho. Además, actúa como fungicida y bactericida eficaz, lo que lo hace valioso en aplicaciones agrícolas. Su alta pureza y estabilidad garantizan un rendimiento constante, lo que lo convierte en la opción preferida de los fabricantes de diversas industrias.