Premium 1,4-Butynediol for Industrial Synthesis

Introduction to 1,4-Butynediol

1,4-Butynediol (C4H6O2) is a vital organic chemical intermediate with significant industrial importance. As a four-carbon diol containing a triple bond, its unique molecular structure enables diverse reactivity patterns. Understanding related compounds like 1-butyne structure and 2-butyne formula provides essential context for appreciating the distinctive chemical behavior of this compound.

Key Structural Relationships

While 1-butyne structure (HC≡C-CH2-CH3) and 2-butyne structural formula (CH3-C≡C-CH3) represent terminal and internal alkynes respectively, 1,4-butynediol (HO-CH2-C≡C-CH2-OH) positions hydroxyl groups at both ends of an alkyne chain, enabling bifunctional reactivity. This structural arrangement supports dual reaction pathways: alkyne transformations and alcohol functionalities.

The global market for 1,4-butynediol is experiencing robust growth, projected to reach $780 million by 2028, with a CAGR of 5.7%. This expansion is driven by increasing demand across pharmaceutical manufacturing, specialty polymers, and corrosion inhibitors. Recent technological advances in selective hydrogenation processes have significantly improved production efficiencies and reduced manufacturing costs.

Technical Specifications and Properties

| Parameter | Specification | Test Method | Significance |

|---|---|---|---|

| Chemical Formula | C4H6O2 | Elemental Analysis | Molecular composition |

| Molecular Weight | 86.09 g/mol | Mass Spectrometry | Dosage calculations |

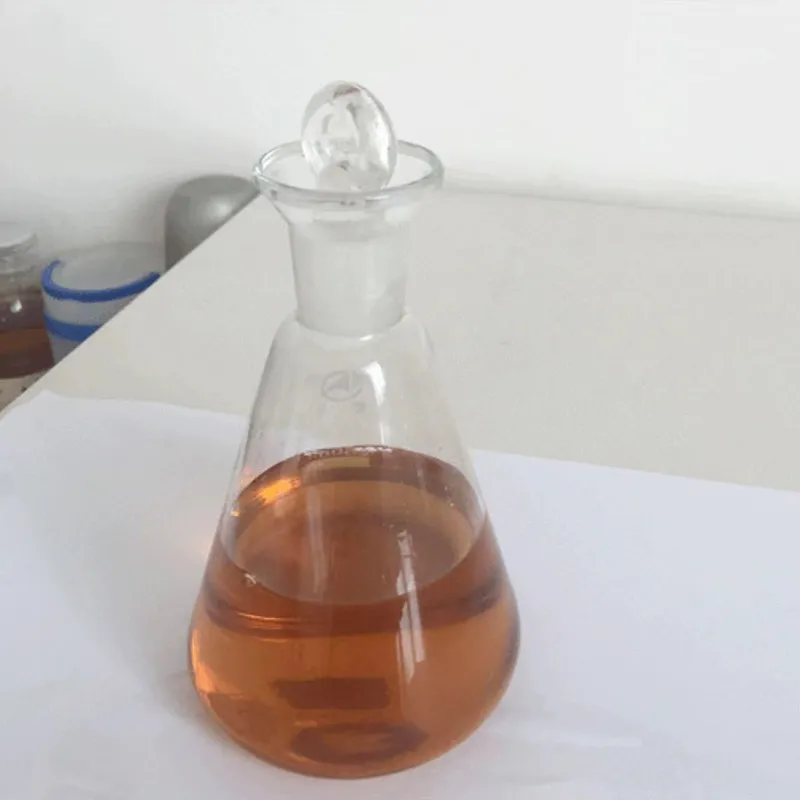

| Appearance | White crystalline solid | Visual Inspection | Purity indicator |

| Melting Point | 58-61°C | DSC | Processing temperature |

| Boiling Point | 145°C at 10 mmHg | Distillation | Purification parameters |

| Density | 1.21 g/cm³ at 20°C | Pyknometer | Transport & storage |

| Solubility | Water: 400 g/L (20°C) | Titration | Formulation compatibility |

| Purity (HPLC) | ≥99.5% | HPLC-UV | Pharmaceutical suitability |

| Flash Point | 128°C (closed cup) | ASTM D93 | Safety handling |

| Storage Temperature | 2-8°C (recommended) | Stability testing | Shelf-life preservation |

Industrial Applications

Pharmaceutical Manufacturing

1,4-Butynediol serves as a critical intermediate in synthesizing various pharmaceutical compounds, particularly GABA analogs and vitamin B6 precursors. The compound's alkyne functionality enables click chemistry approaches for drug conjugation, while its diol structure provides points for further derivatization. Its stereochemical properties influence the chirality of resulting biologically active molecules.

Electroplating & Metal Finishing

In electroplating baths, 1,4-butynediol functions as a brightening agent that improves the microstructural properties of deposited metal layers. Industrial studies demonstrate concentration optimizations between 30-50 ppm yield maximum brightness in nickel plating without compromising deposit ductility. Recent advances include synergistic formulations with novel surfactants for nanocrystalline deposition.

Polymer Chemistry

The unique properties of 1,4-butynediol enable the synthesis of specialized polymers including:

- Photocurable resins for 3D printing applications

- Water-soluble conductive polymers

- Crosslinkable elastomers with tailored hardness

- Biodegradable polyester precursors

Technical Questions & Answers

A: Optimal preservation requires storage in airtight container111s at controlled temperatures (2-8°C) under inert atmosphere. Exposure to moisture should be minimized to prevent hydration and polymerization reactions. Under proper conditions, shelf life exceeds 24 months.

A: While both contain C4 alkyne structures, the 2-butyne formula (CH3C≡CCH3) has terminal methyl groups, whereas 1,4-butynediol positions hydroxyl groups at both molecular terminals (HOCH2C≡CCH2OH), enabling bifunctional chemistry not possible with symmetric alkynes.

A: Technical grade (≥98% purity) suits electroplating applications, while pharmaceutical synthesis requires ultra-high purity grades (≥99.8%) with strict control over heavy metal impurities (

A: Proper PPE (nitrile gloves, face shield) is mandatory due to skin irritation potential. Respiratory protection is required during dust-generating operations. Fire hazards necessitate grounding protocols during transfer. Compatibility charts should be consulted before mixing with oxidizing agents.

A: Commercial quantities are typically packed in polyethylene-lined steel drums (200kg) or isotanks (up to 20 MT), depending on transportation requirements. Special non-reactive liners prevent degradation during extended transit.

Company Profile

Hebei Tenger Chemical Technology Co., Ltd.

As a leading specialty chemical manufacturer, we maintain GMP-compliant facilities producing premium-grade 1,4-Butynediol for global distribution. Our quality management systems are ISO 9001:2015 certified, with dedicated production lines producing pharmaceutical, technical, and electronics grade products.

Contact Information

- 📍 Address: 3-2-501, North Courtyard, West District, Jiuli Courtyard, Yuhua District, Shijiazhuang City, Hebei, China

- 📞 Phone: +86-13673136186

- ✉️ Email: yanzhe@tengerchemical.com

- 🌐 Website: www.tengerchemical.com

Product Specifications

Our 1,4-Butynediol is manufactured under strict quality controls:

- Multi-stage distillation purification

- Strict impurity profile control

- Customizable particle size distributions

- Pharmaceutical-grade packaging options

Technical Citations

"Recent advances in selective hydrogenation of alkynols have significantly improved the industrial production efficiency of 1,4-butynediol. Continuous flow reactors with novel Pd-Pb/CaCO3 catalysts demonstrate conversion rates exceeding 95% with minimized over-hydrogenation byproducts."

Source: Industrial & Engineering Chemistry Research, 2022 https://pubs.acs.org/doi/10.1021/acs.iecr.2c01765

"The molecular architecture of 1,4-butynediol enables unique polymerization pathways for developing functional hydrogel networks. Dual-cure systems incorporating this monomer show promising results in 4D printing applications requiring post-fabrication shape morphing."

Source: Journal of Polymer Science https://onlinelibrary.wiley.com/doi/full/10.1002/pol.20220051

"Electrochemical studies demonstrate that optimized concentrations of 1,4-butynediol in nickel electroplating baths produce exceptionally smooth deposits with hardness values exceeding 500 HV. The leveling mechanism operates through adsorption-induced inhibition at cathode asperities."

Source: Electrochimica Acta https://www.sciencedirect.com/science/article/abs/pii/S0013468622011131

Market Trends and Future Outlook

The application landscape for 1,4-butynediol is evolving rapidly. Beyond traditional uses, emerging applications include:

- Lithium-Ion Battery Additives: Improves electrolyte stability and SEI formation

- Agriculture: Precursor for novel plant growth regulators

- Water Treatment: Corrosion inhibitor in cooling tower systems

- Cosmetics: Chelating agent in anti-aging formulations

Production innovation continues to advance, particularly in China-based facilities that now account for over 65% of global manufacturing capacity. Environmental regulations are driving adoption of closed-loop processes that recover solvents and catalysts. Future research directions include biocatalytic production routes and nanoparticle formulations for targeted drug delivery systems.

-

What Is a Food Additive? Global Insights, Applications & Future TrendsNewsNov.24,2025

-

968 Sweetener: The Modern Solution for Health-Conscious SweeteningNewsNov.23,2025

-

Discover the Benefits and Uses of 965 Sweetener (Erythritol) | Tenger ChemicalNewsNov.23,2025

-

961 Sweetener - A Next-Gen Sugar Alternative for Health and IndustryNewsNov.23,2025

-

Understanding 960 Sweetener: The Modern Sugar Alternative for Health and IndustryNewsNov.22,2025

-

Everything You Need to Know About 955 950 Sweeteners – Benefits, Uses, and TrendsNewsNov.22,2025

-

953 Sweetener: Global Insights, Applications, and Future TrendsNewsNov.21,2025

Hebei Tenger Chemical Technology Co., Ltd. focuses on the chemical industry and is committed to the export service of chemical raw materials.

-

view more DiethanolisopropanolamineIn the ever-growing field of chemical solutions, diethanolisopropanolamine (DEIPA) stands out as a versatile and important compound. Due to its unique chemical structure and properties, DEIPA is of interest to various industries including construction, personal care, and agriculture. -

view more TriisopropanolamineTriisopropanolamine (TIPA) alkanol amine substance, is a kind of alcohol amine compound with amino and alcohol hydroxyl, and because of its molecules contains both amino and hydroxyl. -

view more Tetramethyl Thiuram DisulfideTetramethyl thiuram disulfide, also known as TMTD, is a white to light-yellow powder with a distinct sulfur-like odor. It is soluble in organic solvents such as benzene, acetone, and ethyl acetate, making it highly versatile for use in different formulations. TMTD is known for its excellent vulcanization acceleration properties, which makes it a key ingredient in the production of rubber products. Additionally, it acts as an effective fungicide and bactericide, making it valuable in agricultural applications. Its high purity and stability ensure consistent performance, making it a preferred choice for manufacturers across various industries.