Jan. . 14, 2025 10:11

Back to list

acid mine drainage reaction

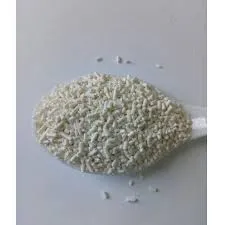

Deep beneath the surface of the Earth, hidden treasures of soda ash await discovery, nurturing industries and communities alike. Soda ash mining is an ancient yet evolving field that demands both expertise and innovation to unlock its potential. This article delves into the multifaceted process of soda ash mining, illuminating the paths that lead to sustainable and efficient operations.

The global demand for soda ash spans numerous industries, from glass manufacturing to chemicals and detergents. Its versatility highlights its economic significance, particularly in the production of flat glass for construction and automotive industries, which rely heavily on high-grade soda ash. Manufacturers consistently seek soda ash mined and processed with efficiency and sustainability, underlining the importance of maintaining robust and eco-friendly practices throughout the supply chain. Sustainability is not only a buzzword but a core tenet of modern soda ash mining. Companies now prioritize reducing their carbon footprint, with many investing in new technologies to achieve cleaner production. For instance, implementing closed-loop systems in processing plants helps in recycling water and minimizing waste. Additionally, adopting renewable energy sources to power mining operations is becoming increasingly common, reflecting a commitment to environmental stewardship. One cannot overlook the social implications of soda ash mining, particularly in regions where it serves as a major economic driver. Employment opportunities emerge not just in mining operations but also in ancillary industries such as transport and logistics. Equally important is the contribution to local development through community-centered initiatives, highlighting the broader impact of responsible mining on human lives. To sustain a thriving soda ash industry, trust is paramount—trust in the data that guides decision-making, in the expertise of seasoned professionals, and in the commitment to social and environmental responsibility. Only with trust can the industry continue to evolve, meeting global demands while safeguarding the planet for future generations. Soda ash mining, therefore, is more than an economic backbone; it is a testament to human ingenuity and our collective responsibility to harmonize industry and nature.

The global demand for soda ash spans numerous industries, from glass manufacturing to chemicals and detergents. Its versatility highlights its economic significance, particularly in the production of flat glass for construction and automotive industries, which rely heavily on high-grade soda ash. Manufacturers consistently seek soda ash mined and processed with efficiency and sustainability, underlining the importance of maintaining robust and eco-friendly practices throughout the supply chain. Sustainability is not only a buzzword but a core tenet of modern soda ash mining. Companies now prioritize reducing their carbon footprint, with many investing in new technologies to achieve cleaner production. For instance, implementing closed-loop systems in processing plants helps in recycling water and minimizing waste. Additionally, adopting renewable energy sources to power mining operations is becoming increasingly common, reflecting a commitment to environmental stewardship. One cannot overlook the social implications of soda ash mining, particularly in regions where it serves as a major economic driver. Employment opportunities emerge not just in mining operations but also in ancillary industries such as transport and logistics. Equally important is the contribution to local development through community-centered initiatives, highlighting the broader impact of responsible mining on human lives. To sustain a thriving soda ash industry, trust is paramount—trust in the data that guides decision-making, in the expertise of seasoned professionals, and in the commitment to social and environmental responsibility. Only with trust can the industry continue to evolve, meeting global demands while safeguarding the planet for future generations. Soda ash mining, therefore, is more than an economic backbone; it is a testament to human ingenuity and our collective responsibility to harmonize industry and nature.

Next:

Latest news

-

PE and PP Plastics with Benzotriazole AdditivesNewsJun.12,2025

-

How Glacial Acetic Acid Balances pH to Combat Food SpoilageNewsJun.12,2025

-

Food Additives in China: Embracing the GreenNewsJun.12,2025

-

Cyanide Mining Gold Extraction and the Rise of Complementary ChemicalsNewsJun.12,2025

-

Ammonium Nitrate in Pharmaceutical ManufacturingNewsJun.12,2025

-

Aluminum Hydroxide in Glass and Ceramics ManufacturingNewsJun.12,2025

-

Mining Chemicals: Cyanide in Gold MiningNewsJun.04,2025

HOT PRODUCTS

Hebei Tenger Chemical Technology Co., Ltd. focuses on the chemical industry and is committed to the export service of chemical raw materials.

-

view more DiethanolisopropanolamineIn the ever-growing field of chemical solutions, diethanolisopropanolamine (DEIPA) stands out as a versatile and important compound. Due to its unique chemical structure and properties, DEIPA is of interest to various industries including construction, personal care, and agriculture. -

view more TriisopropanolamineTriisopropanolamine (TIPA) alkanol amine substance, is a kind of alcohol amine compound with amino and alcohol hydroxyl, and because of its molecules contains both amino and hydroxyl. -

view more Tetramethyl Thiuram DisulfideTetramethyl thiuram disulfide, also known as TMTD, is a white to light-yellow powder with a distinct sulfur-like odor. It is soluble in organic solvents such as benzene, acetone, and ethyl acetate, making it highly versatile for use in different formulations. TMTD is known for its excellent vulcanization acceleration properties, which makes it a key ingredient in the production of rubber products. Additionally, it acts as an effective fungicide and bactericide, making it valuable in agricultural applications. Its high purity and stability ensure consistent performance, making it a preferred choice for manufacturers across various industries.