Fév . 19, 2025 11:44

Back to list

Monosodium Glutamate (MSG)

Unlocking the Secrets of Monosodium Glutamate Production A Journey from Expertise to Consumer Trust

Establishing Authority and Trust MSG production is not merely about chemical reactions; it is also about establishing trust. Factories operate under rigorous quality control protocols, often surpassing local and international food safety regulations. Regular audits and certifications further cement the credibility of MSG producers as authorities in food safety and quality. Production facilities showcase cutting-edge technology and innovation. Automation and real-time monitoring systems facilitate consistent quality assurance, fostering consumer confidence. The transparency of these processes and adherence to the highest standards are crucial in dispelling myths and misinformation surrounding MSG. A Taste of Experience Consumers benefit from the rich umami flavor imparted by MSG in their food. This hallmark taste is rooted in the extensive experience manufacturers bring to the table. Their commitment to excellence is evidenced in the stringent testing and research underpinning each batch of MSG produced. The complexities of the production cycle, honed over decades, are distilled into a single, perfect spoonful of flavor-enhancing powder. Innovation in MSG production does not rest on its laurels. Continuous research and development explore greener production methods, such as reducing carbon footprint and optimizing resource efficiency. This forward-thinking approach blends traditional expertise with modern sustainability goals, reinforcing the trust consumers place in MSG products. Concluding Thoughts The MSG production process embodies a blend of scientific expertise, authoritative practice, and trustworthy operations. The path from simple sugars to a complex flavor enhancer highlights the dedication to quality and safety. As consumers delight in the culinary pleasures that MSG facilitates, understanding its production process assures them of the care and expertise invested in every pinch. The commitment to transparency, innovation, and consumer trust makes MSG an enduring staple, not just in kitchens, but also in the world of food science.

Establishing Authority and Trust MSG production is not merely about chemical reactions; it is also about establishing trust. Factories operate under rigorous quality control protocols, often surpassing local and international food safety regulations. Regular audits and certifications further cement the credibility of MSG producers as authorities in food safety and quality. Production facilities showcase cutting-edge technology and innovation. Automation and real-time monitoring systems facilitate consistent quality assurance, fostering consumer confidence. The transparency of these processes and adherence to the highest standards are crucial in dispelling myths and misinformation surrounding MSG. A Taste of Experience Consumers benefit from the rich umami flavor imparted by MSG in their food. This hallmark taste is rooted in the extensive experience manufacturers bring to the table. Their commitment to excellence is evidenced in the stringent testing and research underpinning each batch of MSG produced. The complexities of the production cycle, honed over decades, are distilled into a single, perfect spoonful of flavor-enhancing powder. Innovation in MSG production does not rest on its laurels. Continuous research and development explore greener production methods, such as reducing carbon footprint and optimizing resource efficiency. This forward-thinking approach blends traditional expertise with modern sustainability goals, reinforcing the trust consumers place in MSG products. Concluding Thoughts The MSG production process embodies a blend of scientific expertise, authoritative practice, and trustworthy operations. The path from simple sugars to a complex flavor enhancer highlights the dedication to quality and safety. As consumers delight in the culinary pleasures that MSG facilitates, understanding its production process assures them of the care and expertise invested in every pinch. The commitment to transparency, innovation, and consumer trust makes MSG an enduring staple, not just in kitchens, but also in the world of food science.

Latest news

-

Sodium Dichloroisocyanurate Safety Handling ProtocolsNewsJul.29,2025

-

Mining Chemicals for Copper Extraction Processes GuideNewsJul.29,2025

-

Fertilizer for Sale Shipping and Storage TipsNewsJul.29,2025

-

Dimethyl Disulfide as Sulfurizing AgentNewsJul.29,2025

-

Benzotriazole Safety Data Handling and Storage GuidelinesNewsJul.29,2025

-

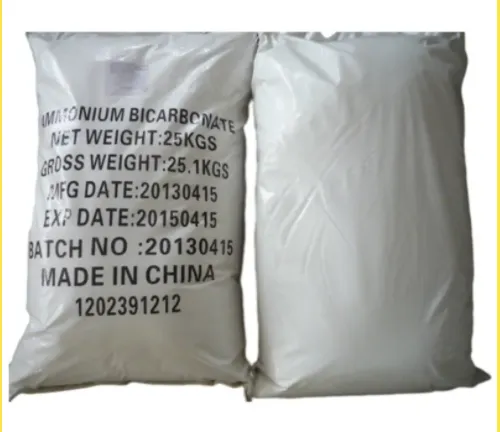

Ammonium Bicarbonate Safety Handling Storage GuidelinesNewsJul.29,2025

-

The Transformative Role Of Trichloroisocyanuric Acid in Water TreatmentNewsJul.23,2025

HOT PRODUCTS

Hebei Tenger Chemical Technology Co., Ltd. focuses on the chemical industry and is committed to the export service of chemical raw materials.

-

view more DiethanolisopropanolamineIn the ever-growing field of chemical solutions, diethanolisopropanolamine (DEIPA) stands out as a versatile and important compound. Due to its unique chemical structure and properties, DEIPA is of interest to various industries including construction, personal care, and agriculture. -

view more TriisopropanolamineTriisopropanolamine (TIPA) alkanol amine substance, is a kind of alcohol amine compound with amino and alcohol hydroxyl, and because of its molecules contains both amino and hydroxyl. -

view more Tetramethyl Thiuram DisulfideTetramethyl thiuram disulfide, also known as TMTD, is a white to light-yellow powder with a distinct sulfur-like odor. It is soluble in organic solvents such as benzene, acetone, and ethyl acetate, making it highly versatile for use in different formulations. TMTD is known for its excellent vulcanization acceleration properties, which makes it a key ingredient in the production of rubber products. Additionally, it acts as an effective fungicide and bactericide, making it valuable in agricultural applications. Its high purity and stability ensure consistent performance, making it a preferred choice for manufacturers across various industries.